PEI’s Decorative Team delivers keepsakes cherished by millions. Ornaments, commemoratives, model parts, and custom jewelry are just some of the things we produce for wholesale customers around the world. Our design and manufacturing experts collaborate with customers to create something unique and special that will last a lifetime.

Our first step is working on the design of your project. We’ll need you to send over images and any other design parameters. From there, we send a color illustration of the project for your approval.

In step two, we discuss metals, finishes, style, delivery dates, packaging, pricing, and signing an agreement. Depending on the time of year, we estimate your project will ship between four and eight weeks later.

PEI uses a manufacturing process called precision chemical machining (also called photochemical etching, chemical blanking, or photochemical machining). Once we have a final design product, we create a phototool (think of it like a negative) and transpose it onto a metal sheet using high-intensity UV lights. We start manufacturing by applying a liquid called photoresist to the metal sheet.

The sheets then go through an etching machine where chemical etchants are sprayed onto the surface, dissolving the metal where there is no photoresist. Your unique pattern or design is visible when that metal sheet leaves the etcher.

Those metal sheets are cleaned and polished before going through the finishing stage. Once your collectible passes inspection, we package it and send it to you.

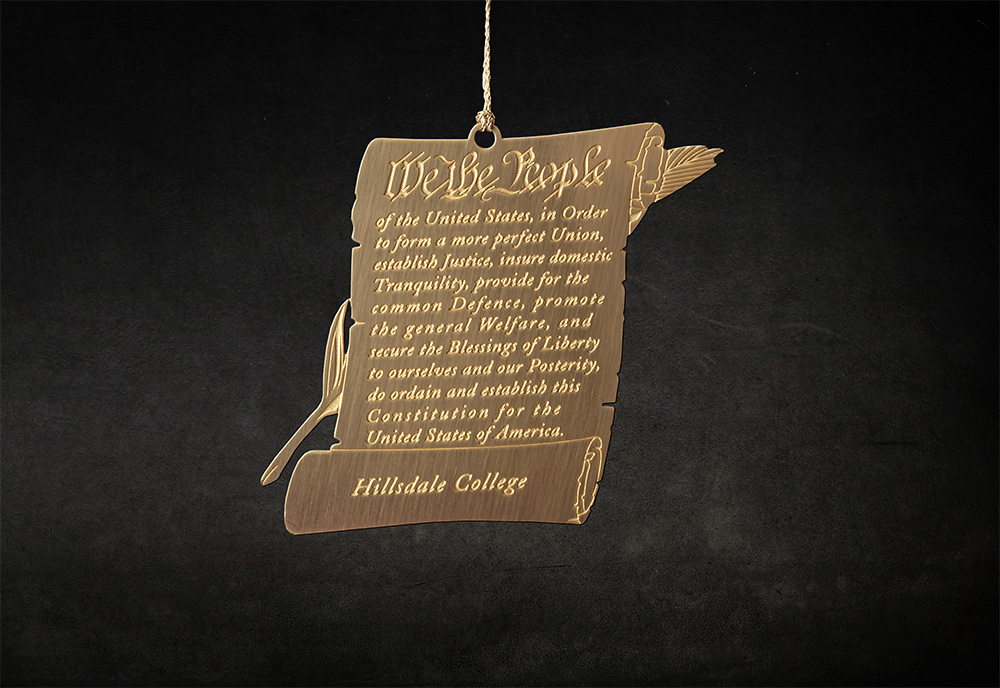

For more than 30 years, PEI’s Decorative Team has worked with corporations, universities, non-profit organizations, and businesses to create beautiful, unique collectibles.

Our team works with customers to perfect their designs, fabricates stunning pieces, packages the collectibles, and ships them directly to you.

Here are just a few of the things we’ve produced: