Precision electronic devices rely on undisturbed signals, especially those used in life-saving medical machines, defense and aerospace applications, and communications hardware.

Shields to reduce or eliminate EMI (electromagnetic interference) or RFI (radio frequency interference) are essential to reducing noise and helping boost the signal to these electronic devices.

PEI is a leading manufacturing partner of industry-leading companies serving the medical, defense, aerospace, and electronics sectors.

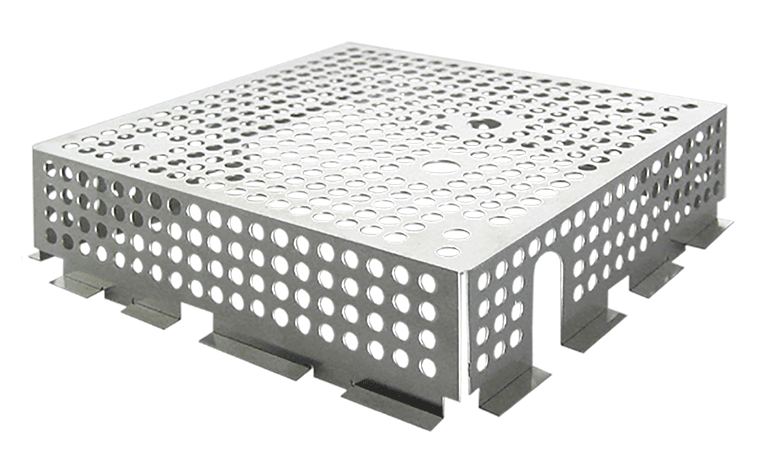

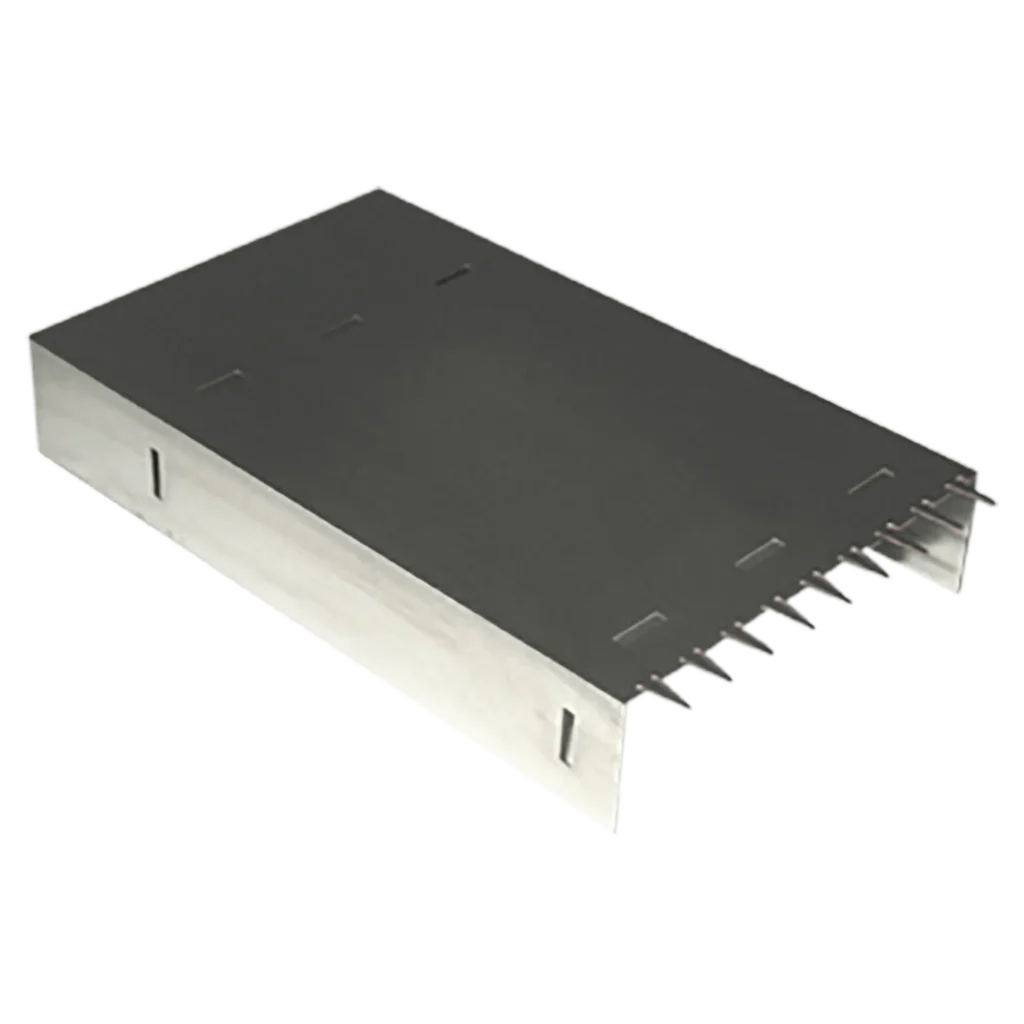

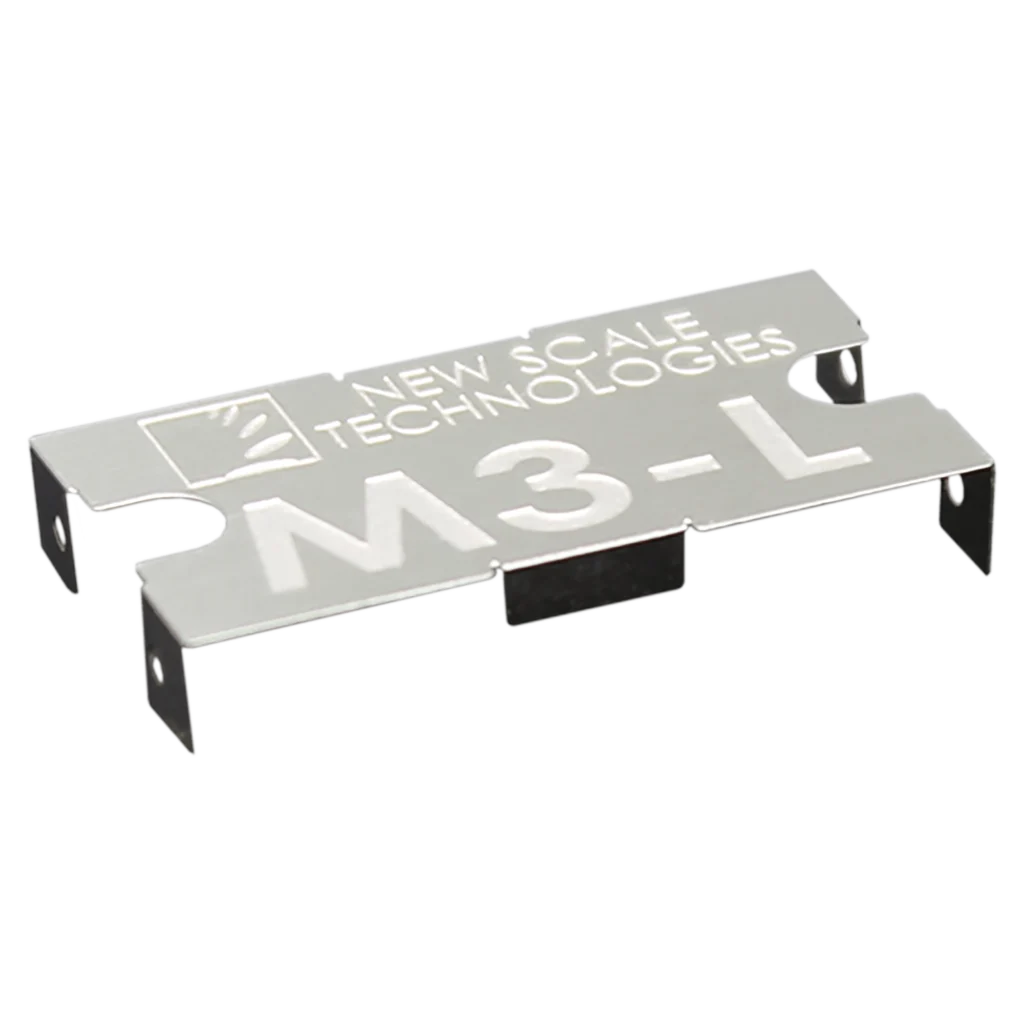

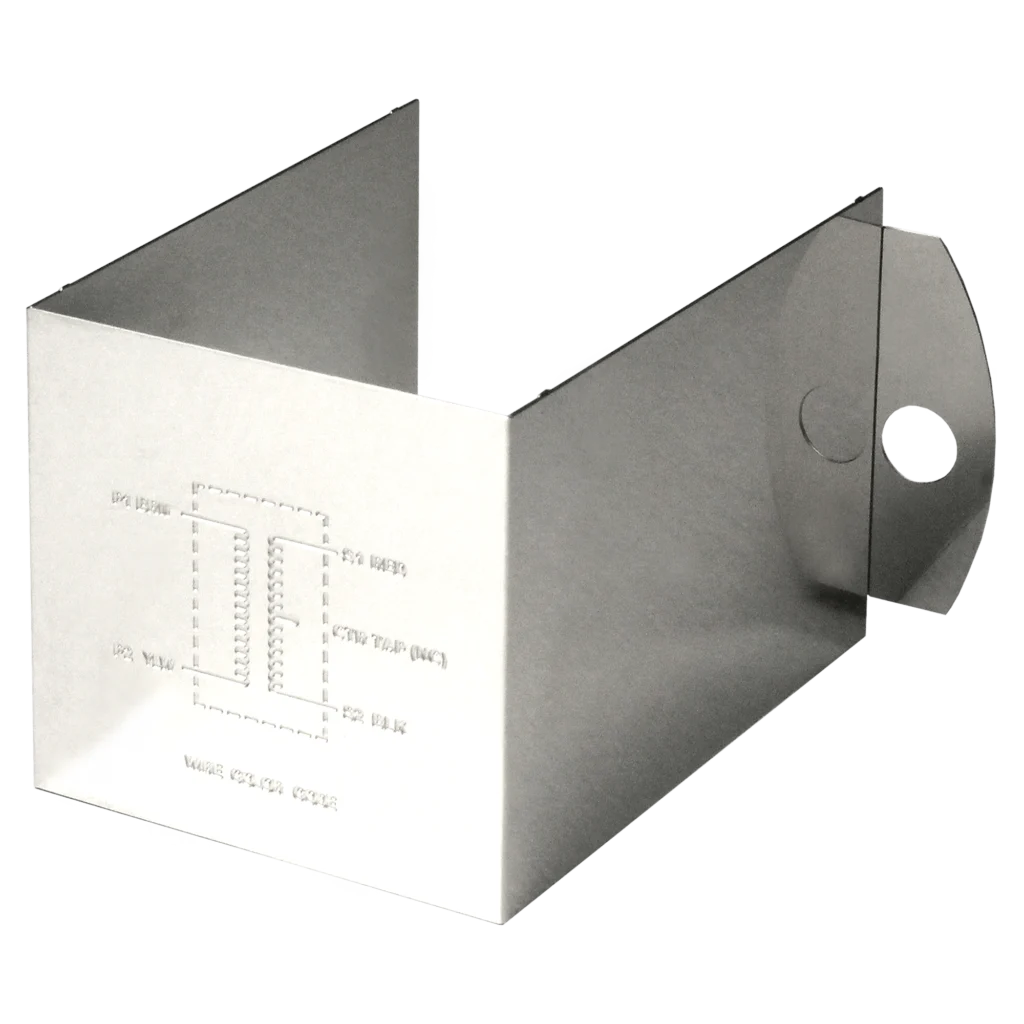

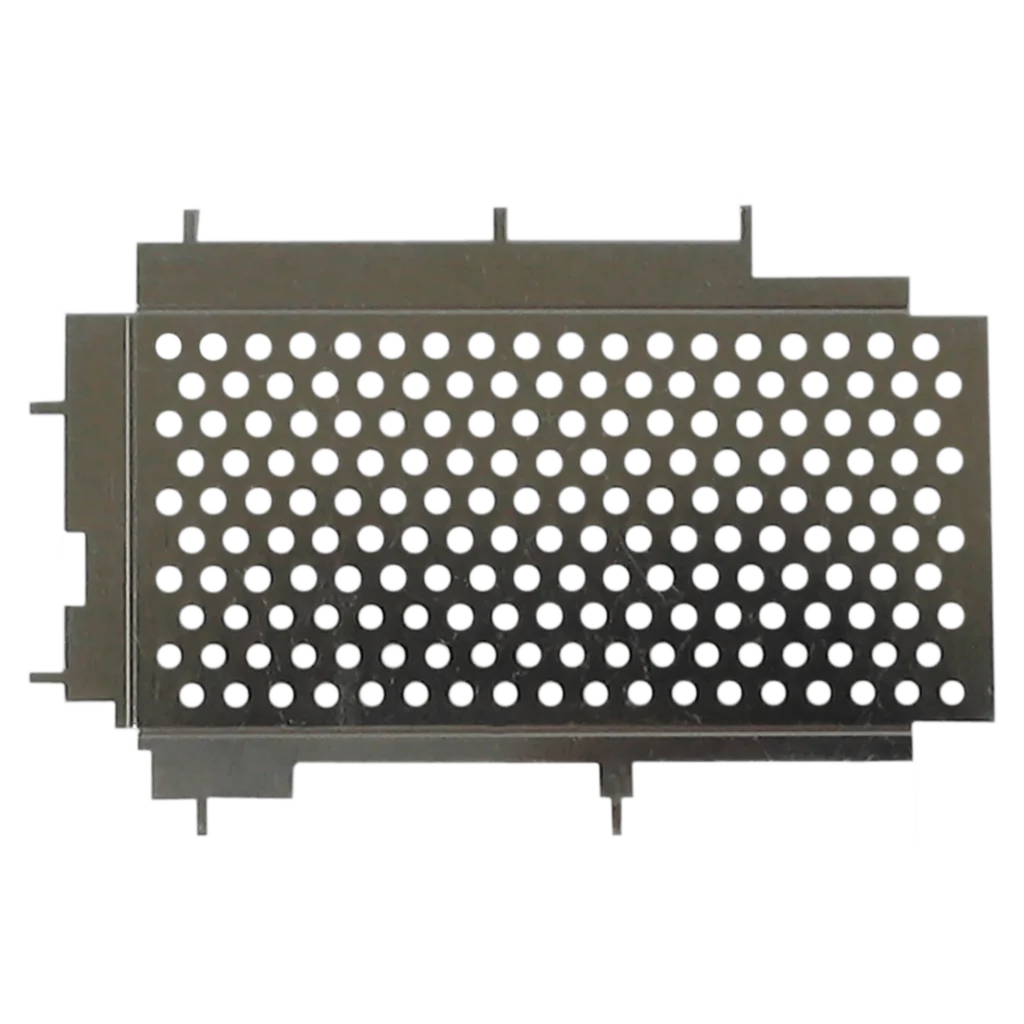

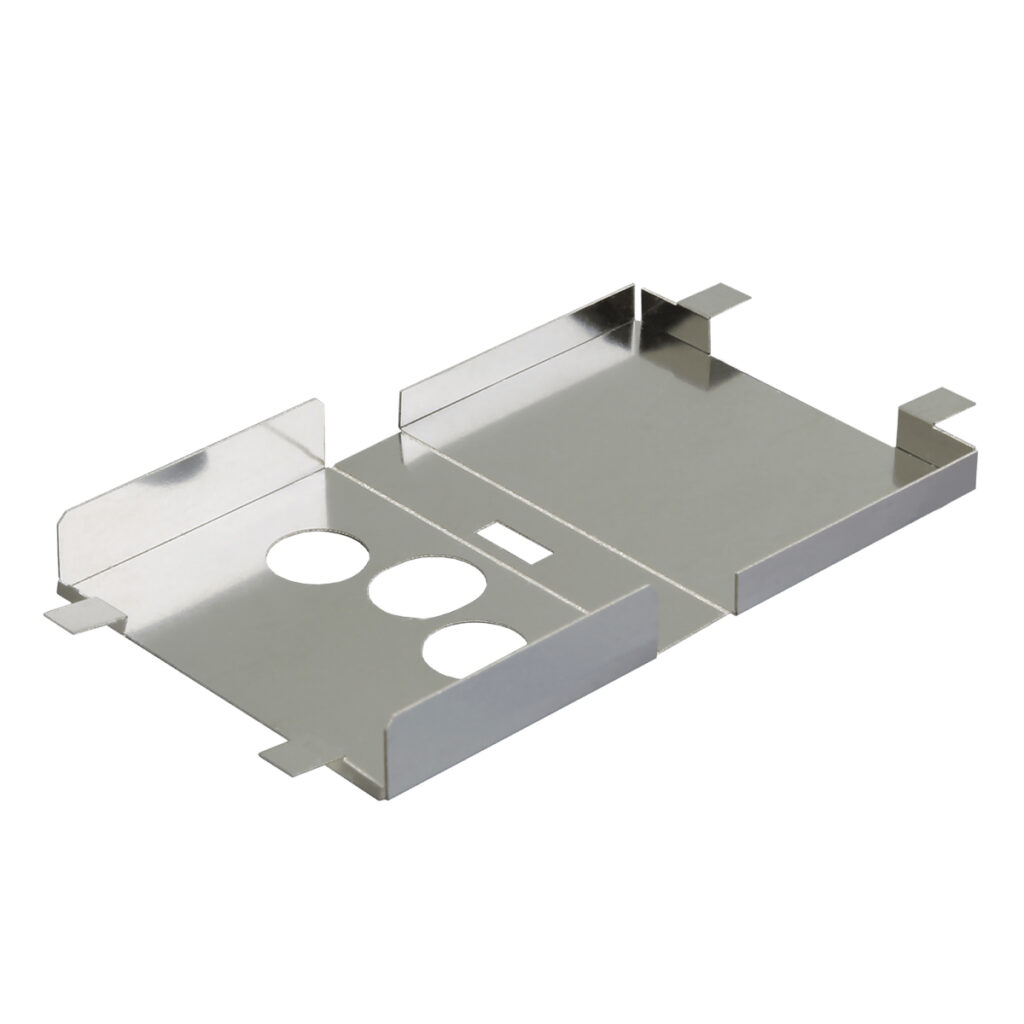

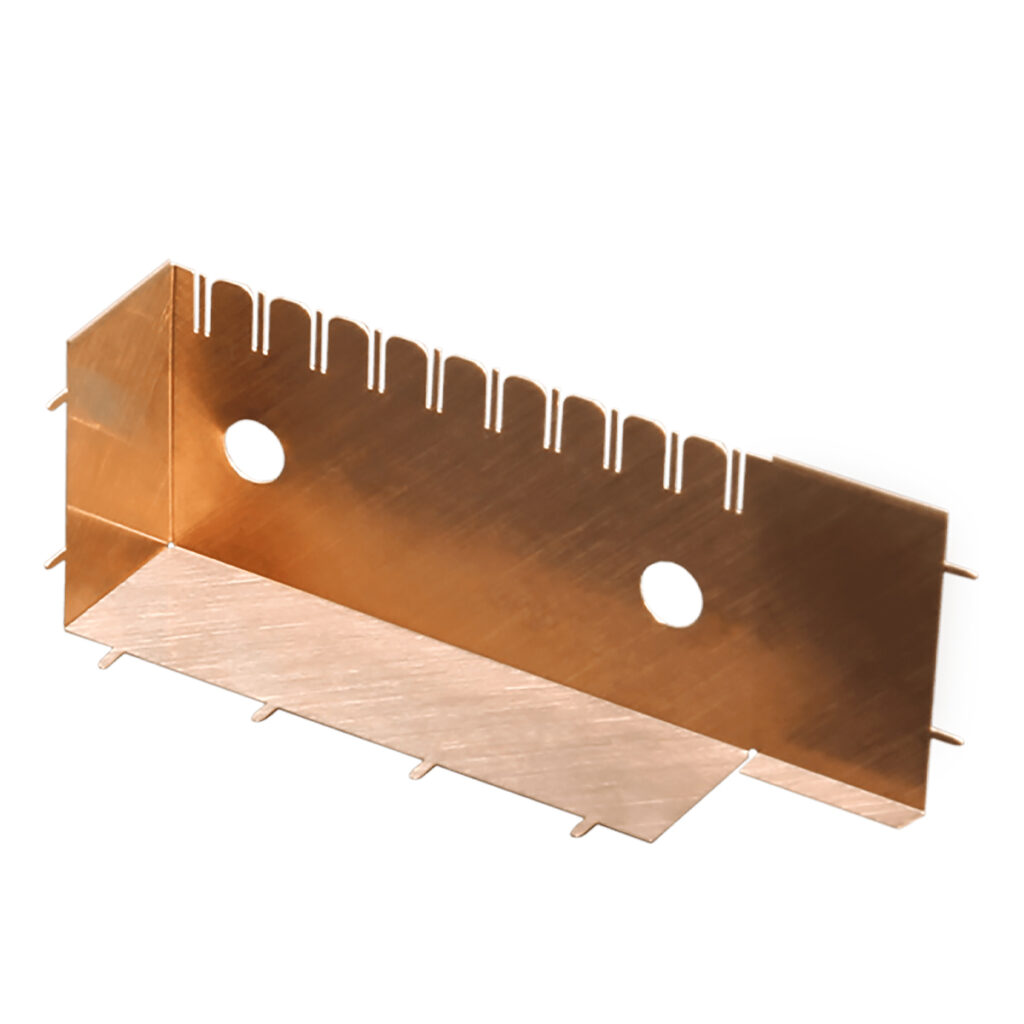

An EMI/RFI shield is a solidly constructed thin metal part that improves electronic devices’ performance, safety, and reliability by blocking interference from outside sources.

The shields are essential to any electronic application because they maintain the integrity of data transmissions and signals and offer protection against the interception of outgoing signals.

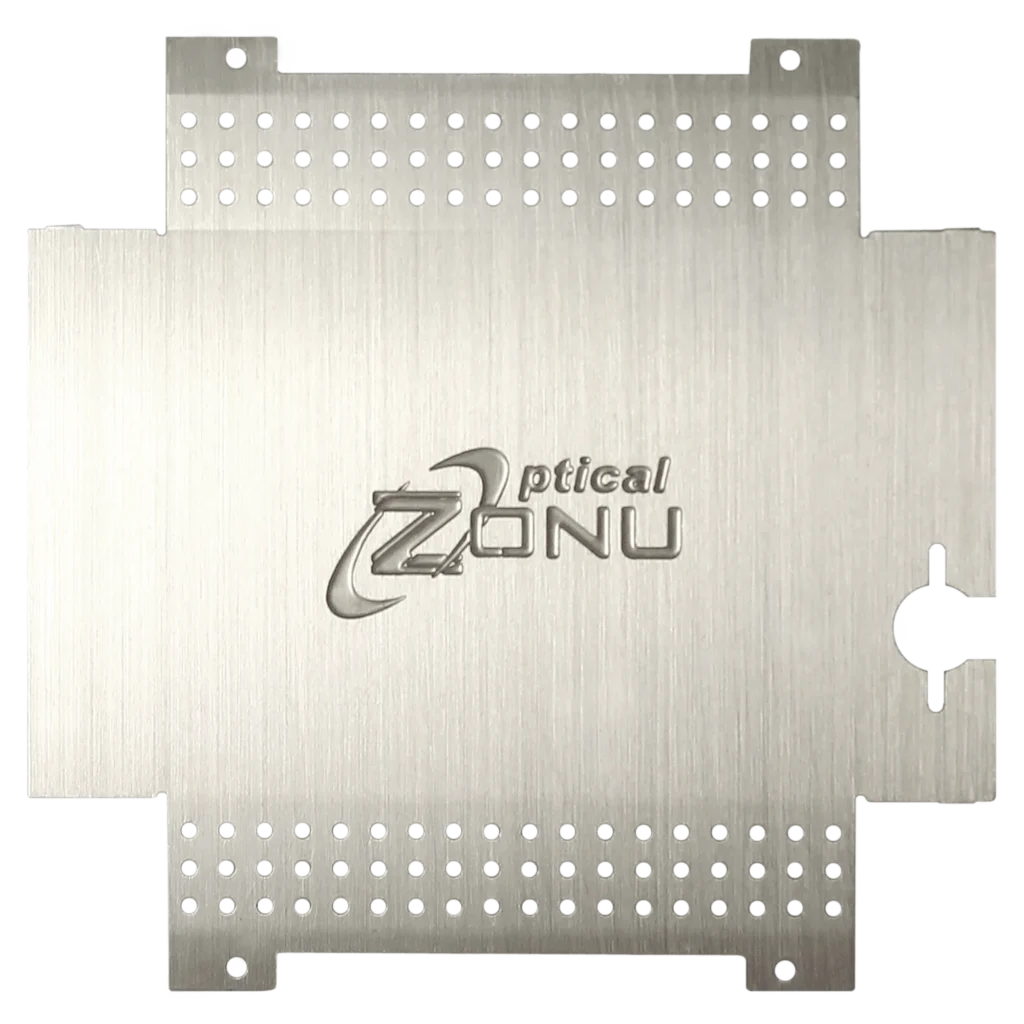

Understanding the distinct roles of EMI and RF/RFI Shielding is pivotal for ensuring the optimal performance and reliability of electronic systems. Our innovative Control Depth Etch (CDE) fold line technology allows us to create 3-dimensional EMI/RF shield solutions from flat sheets, significantly reducing tooling costs and delivery cycle times. CDE fold lines create an easy way to manually bend your custom designs accurately and at various angles, avoiding the expense of hard tooling and the delivery timing associated with it.

EMI Shielding: Protects against electromagnetic interference

RF/RFI Shielding: Protects against radio frequency interference

EMI Shielding: Critical for maintaining signal integrity and preventing system malfunctions

RF/RFI Shielding: Essential for high-frequency applications like telecommunications

EMI Shielding: Aerospace, healthcare, military, and more

RF/RFI Shielding: Telecommunications, wireless devices, and more

EMI Shielding: Conductivity, magnetic permeability, and thickness are key

RF/RFI Shielding: Material conductivity and shield geometry are crucial

EMI Shielding: PEI offers tailored EMI shields to meet industry standards

RF/RFI Shielding: PEI provides custom RF/RFI shields for a wide range of frequencies and uses

Engineers specify various base materials for EMI/RFI shields, depending on the application and industry requirements. Nickel-silver is the most common material choice for EMI/RFI shields, but PEI operators are experts at working with:

Brass

Tin

Tin-lead

Nickel

Copper

Cold-rolled Steel

EMI/RFI shields from these metals can be provided with solderable plating.

EMI/RFI shields are found across several industries, making them one of the most critical parts we produce at PEI. As experts in the production of EMI/RFI shields, PEI services customers in these sectors:

Medical

Defense

Aerospace

Electronics

Automotive

Industrial

Shields prevent interference that could affect diagnostic accuracy and impact patient safety in diagnostic machines like MRIs

Protecting communications and navigation systems is the primary responsibility of shields, especially in aircraft, satellites, and military equipment

Whether in consumer electronics like computers, communications devices like mobile phones, or telecommunications towers, shields reduce interference to increase signal

Photochemical etching, also known as precision chemical machining, chemical blanking, or acid etching, is an exact subtractive manufacturing process where chemical etchants selectively remove metal from a thin sheet to create intricate shapes, patterns, and features. Unlike traditional methods, photochemical machining does not involve mechanical force or direct contact with the sheet of metal, minimizing the risk of distortion, burrs, or stress-induced deformation.

The benefits of photochemically etching carrier plates include fabricating precise parts with intricate geometries and accurate patterns.

Here are additional benefits of titanium photochemical etching:

With a history of engineering excellence, PEI is among the top companies providing photochemically etched metal parts and components for various critical industries.

With ISO-9001:2008 and AS9100 certifications, PEI was also granted certification under the International Traffic in Arms Regulation (ITAR) in 2010, enabling it to provide weapon system components and accessories in compliance with the Code of Federal Regulations implemented by the U.S. Department of State.

Our rigorous inspection processes and testing procedures ensure that every product we produce meets stringent accuracy, reliability, and performance standards.