PEI’s precision chemical machining expertise comes from decades of experience and a daily dedication to perfection. PEI’s manufacturing operators have a 50-plus-year history of producing accurate, durable, and dependable metal parts via precision chemical machining (PCM), also known as photochemical machining, photochemical etching, or chemical blanking. PCM relies on photo tools and chemical etchants to produce a stress-free metal part with efficiency, accuracy, and cost-effectiveness.

The PEI legacy of precision manufacturing dates back to its earliest days when photochemical machining was a new fabrication process. Over the years, our technicians have mastered photochemical machining to produce metal parts used in the most demanding environments for industry leaders in renewable energy, medical, defense, aerospace, and technology.

Our manufacturing team works closely with PEI engineers and quality assurance professionals to ensure that every part meets the stringent standards set by our clients and required by our certification partners.

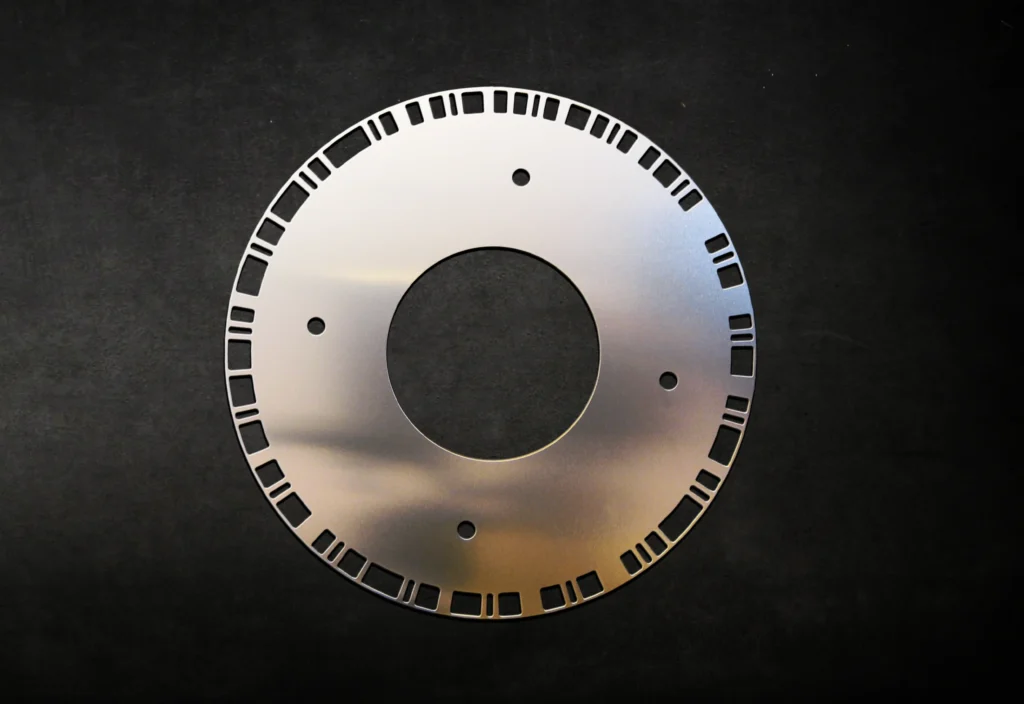

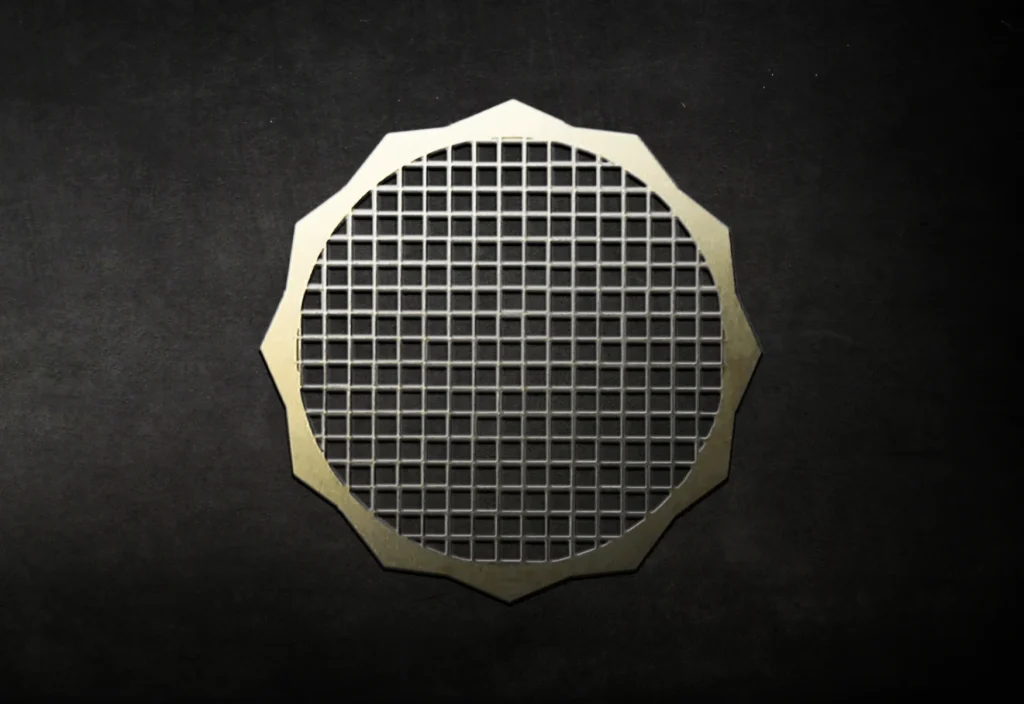

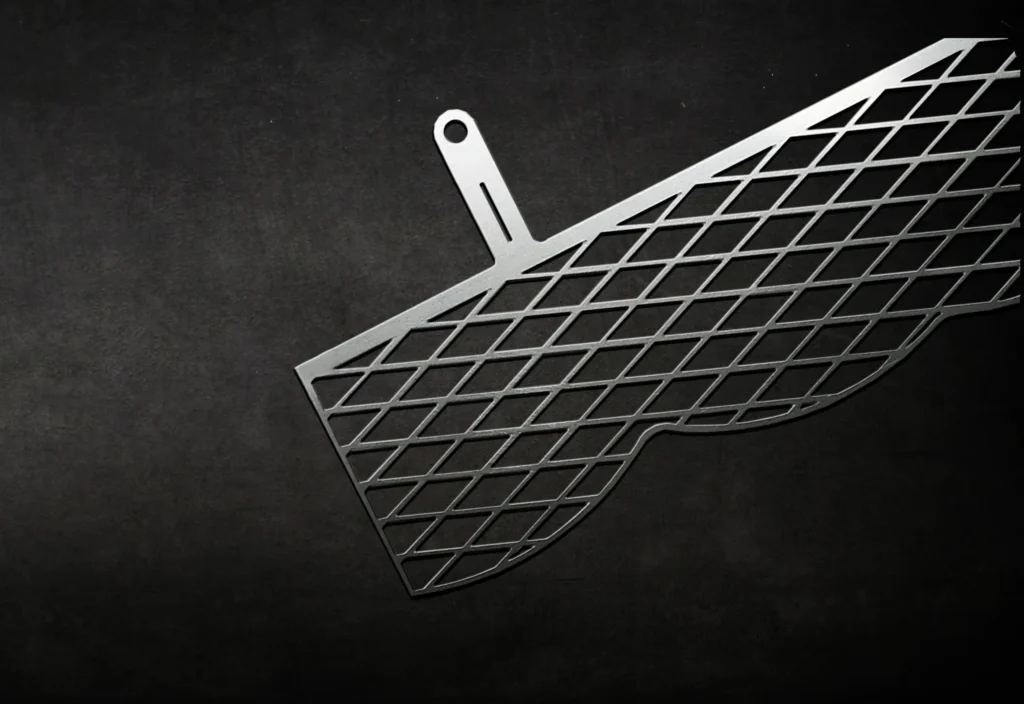

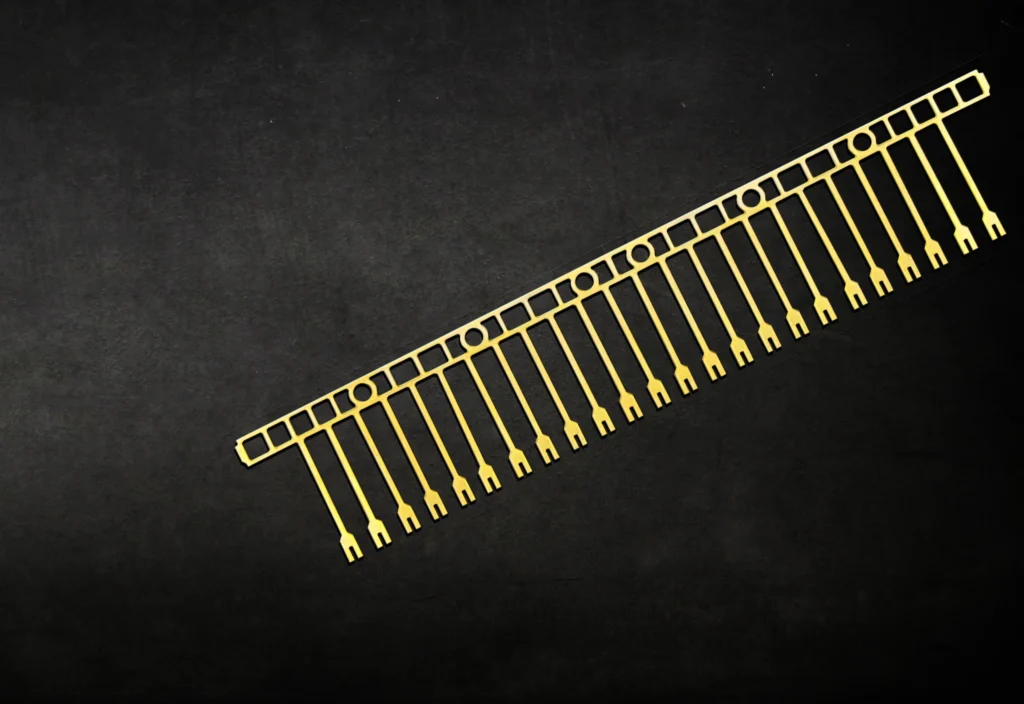

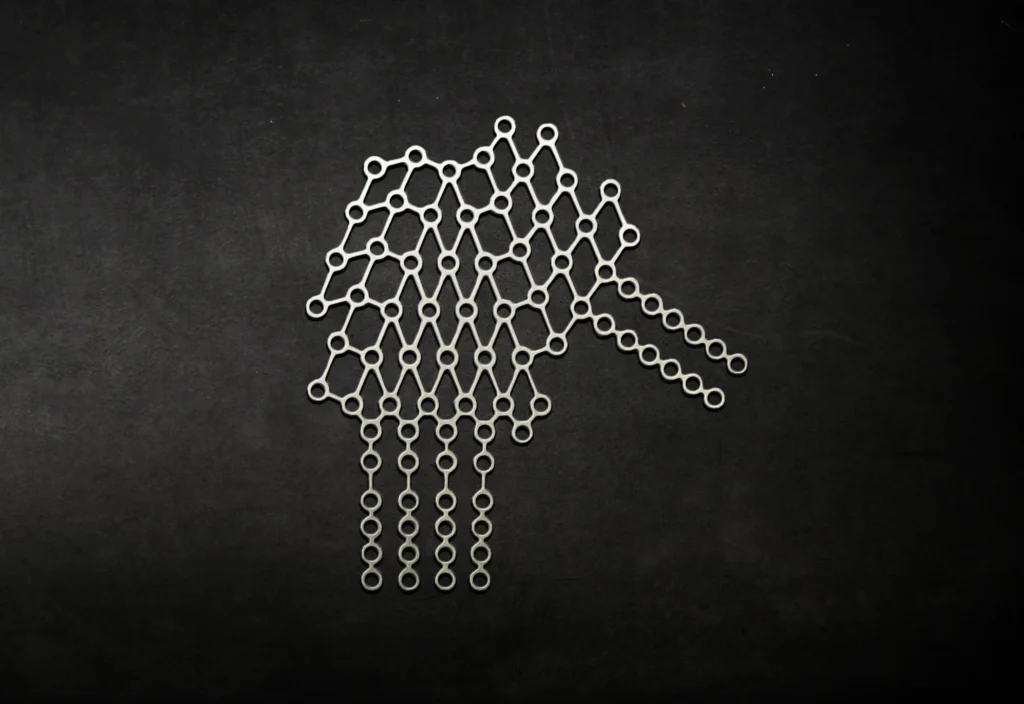

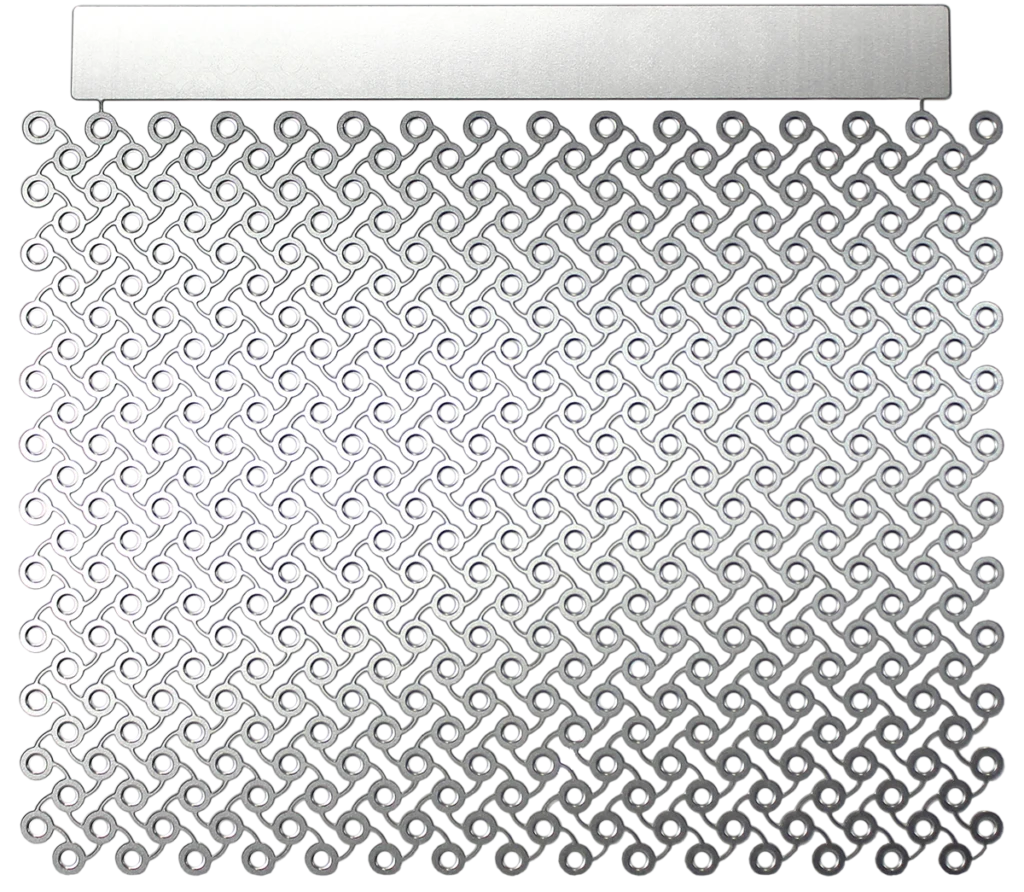

Photochemical machining, also known as precision chemical machining, photochemical etching, or chemical blanking, is a manufacturing process where technicians produce metal parts by dissolving metal unnecessary for the final product by applying etchants in a controlled environment.

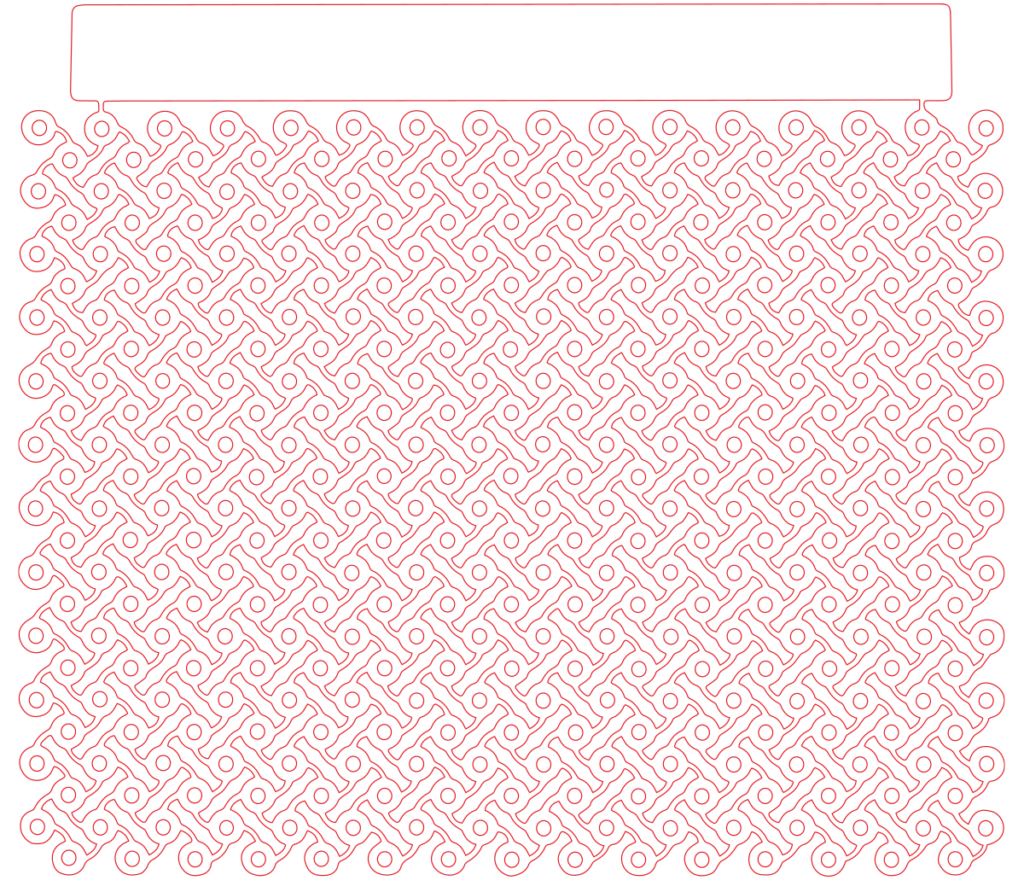

The PCM process begins when engineers deliver part specifications to the manufacturing floor. PEI’s manufacturing experts apply a light-sensitive photoresist coating to the metal, and then the design is impressed on the metal using a photo tool and high-intensity UV lights. The photoresist hardens when exposed to UV light, protecting some parts of the metal from the etchants used to create the part.

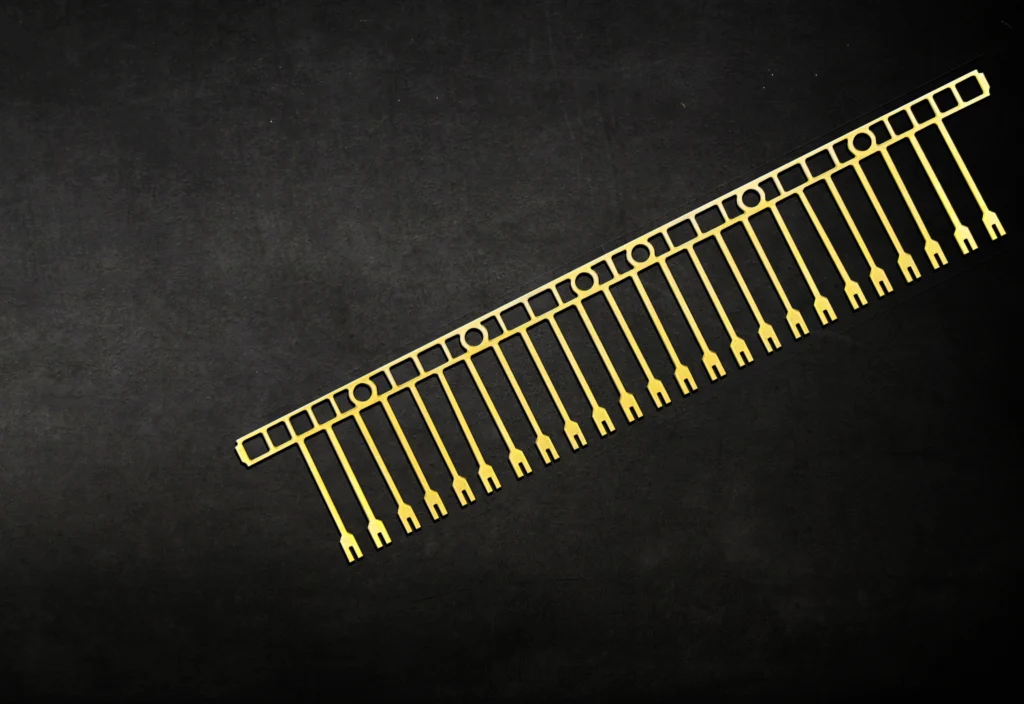

PCM delivers superior results when compared to laser cutting or stamping because the process does not warp the metal or produce burrs — edges that can compromise a part’s integrity and require an additional fabrication process like grinding. Also, PCM enables high-volume production because we can make multiple parts simultaneously versus one part at a time in a laser setting.

The benefits of precision chemical machining include part quality, speed of delivery, and cost-effectiveness. PCM is ideal for rapid prototyping because it doesn’t require expensive setup and tooling and is fast, which means engineers can perfect their designs and get a solution to market sooner.

PEI is the world’s leader in the etching of titanium and specializes in a handful of other metals, including:

We work with our partners to introduce new ideas and enhanced manufacturing solutions. Our engineers leverage the power of technology and decades of experience to ensure each design and plan will deliver the expected results, whether for the latest in renewable energy or a new life-saving medical technology.

Our precision operators turn thin metal parts into reliable components with meticulous machine and manual forming techniques. PEI’s forming expertise starts at the first step, enabling us to develop highly accurate parts that our team forms to exact standards and specifications.

Protecting precision metal parts from corrosion, wear, and environmental hazards is job number one when applying coatings, finishes, plating, or paint. Finishing applications also offer antibiotic and aesthetic benefits to the parts we produce via photochemical etching.

PEI delivers durable and reliable assembled components found in power-generating, life-saving, and high-technology applications worldwide. Our expert team of engineers and operators team to ensure our partners receive ready-to-implement solutions that will last.

The PEI Quality Assurance team analyzes every thin metal part and component to ensure its precision, accuracy, and durability. Our team uses a combination of technological and manual inspection techniques to check for imperfections before any part or component leaves our facility.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.