Stainless steel is a common alloy choice for engineers designing parts and components used in medical, aerospace, electronics, and automotive applications. The material is durable, strong, and resistant to corrosion and heat. It comes in a variety of grades and compositions, making it flexible across a number of applications.

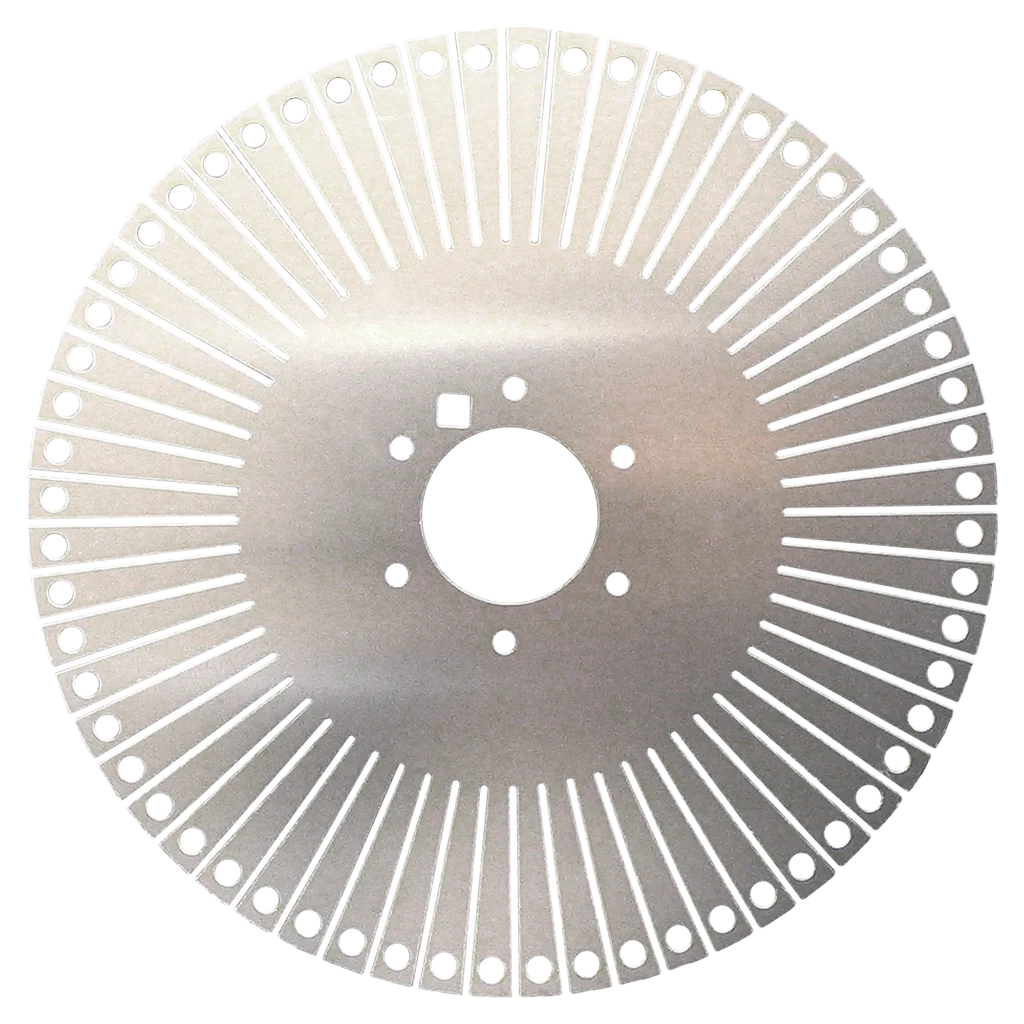

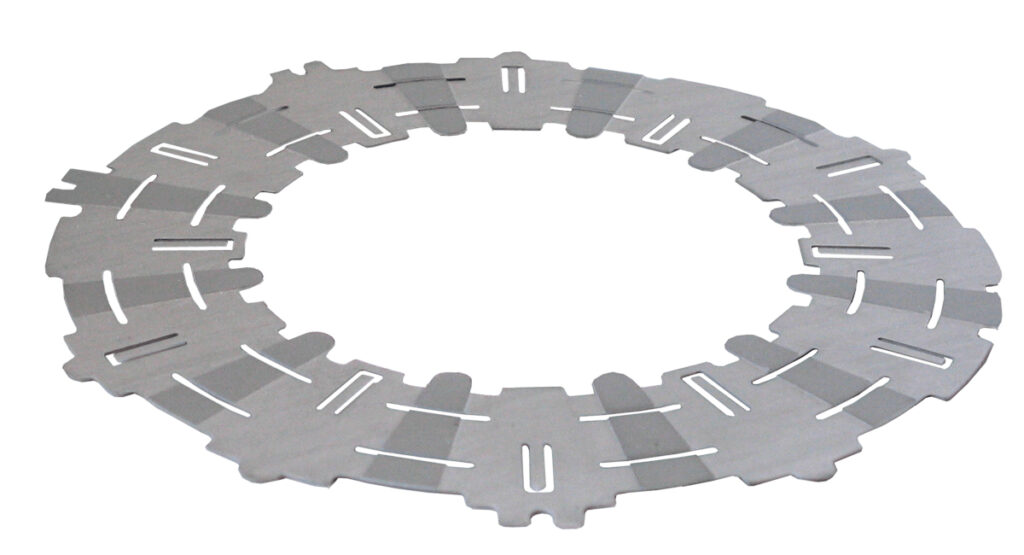

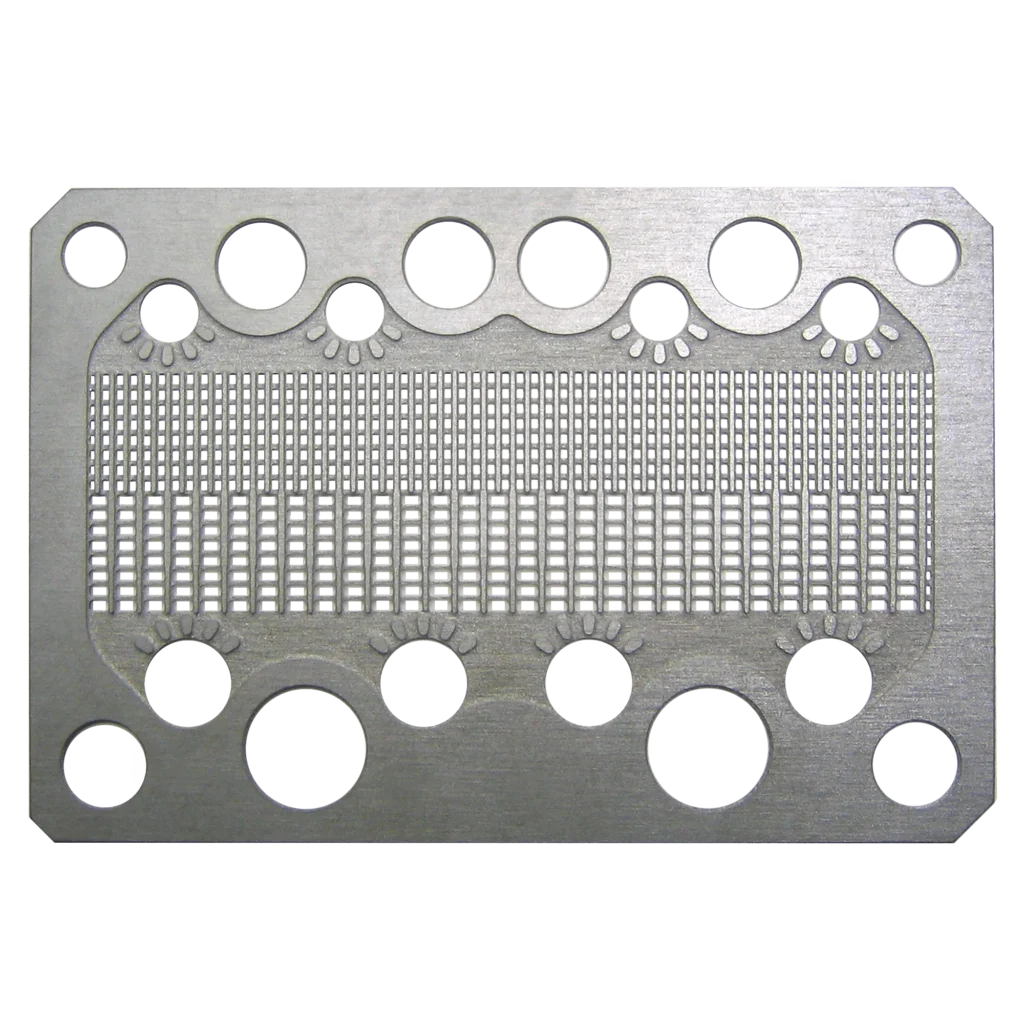

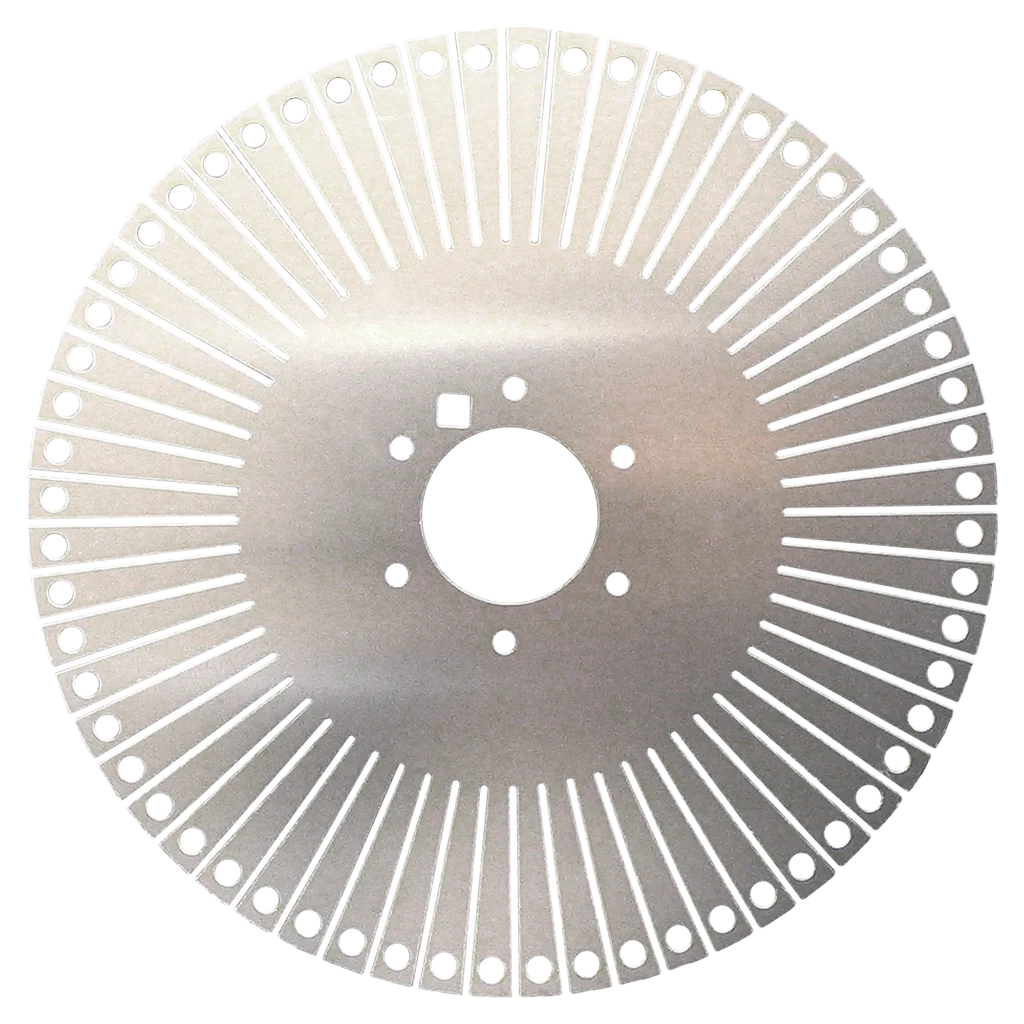

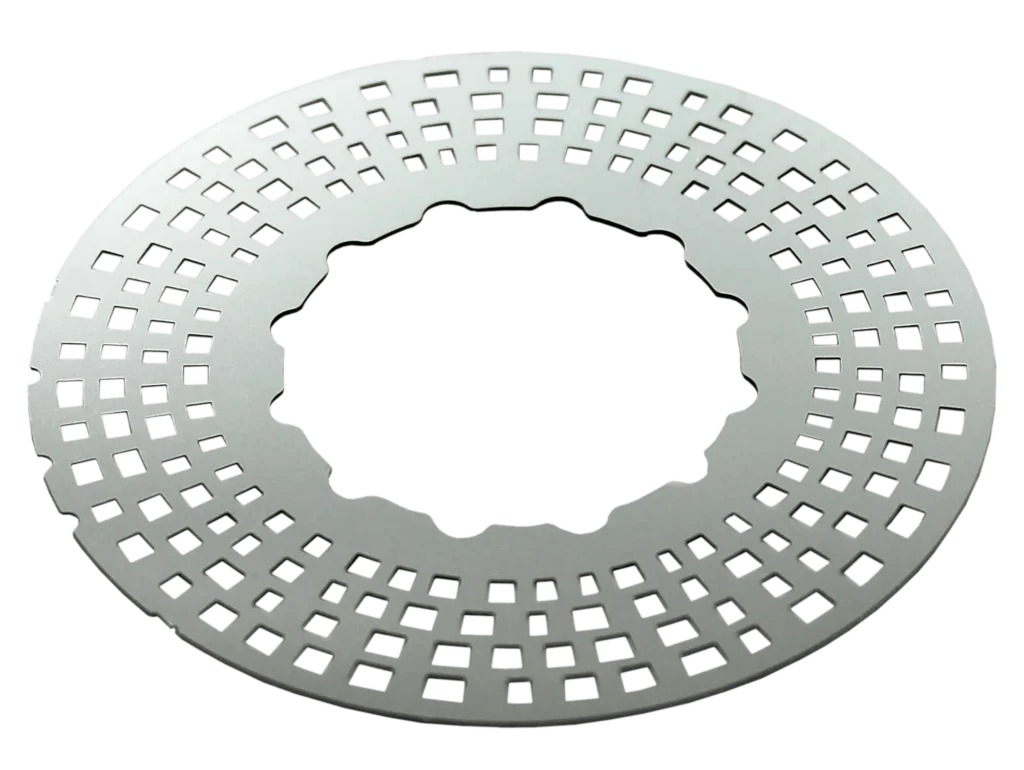

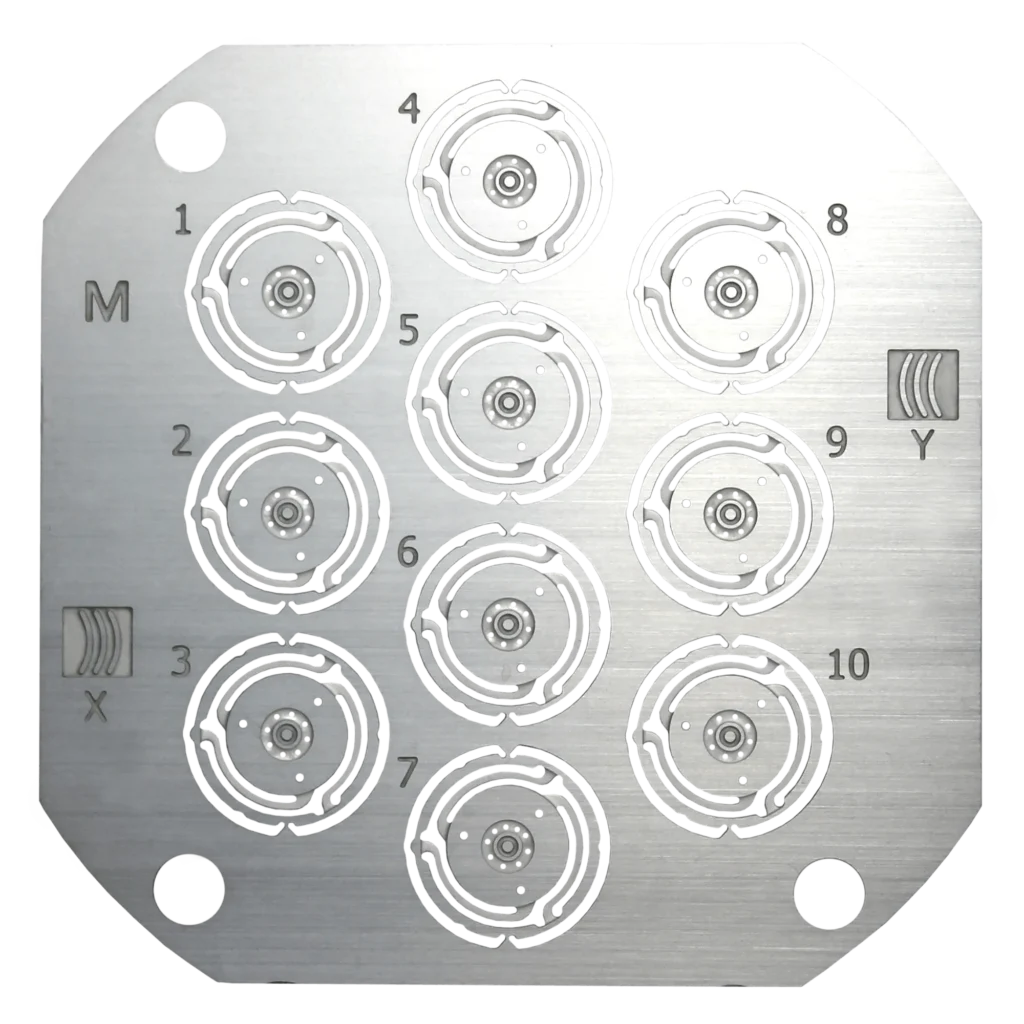

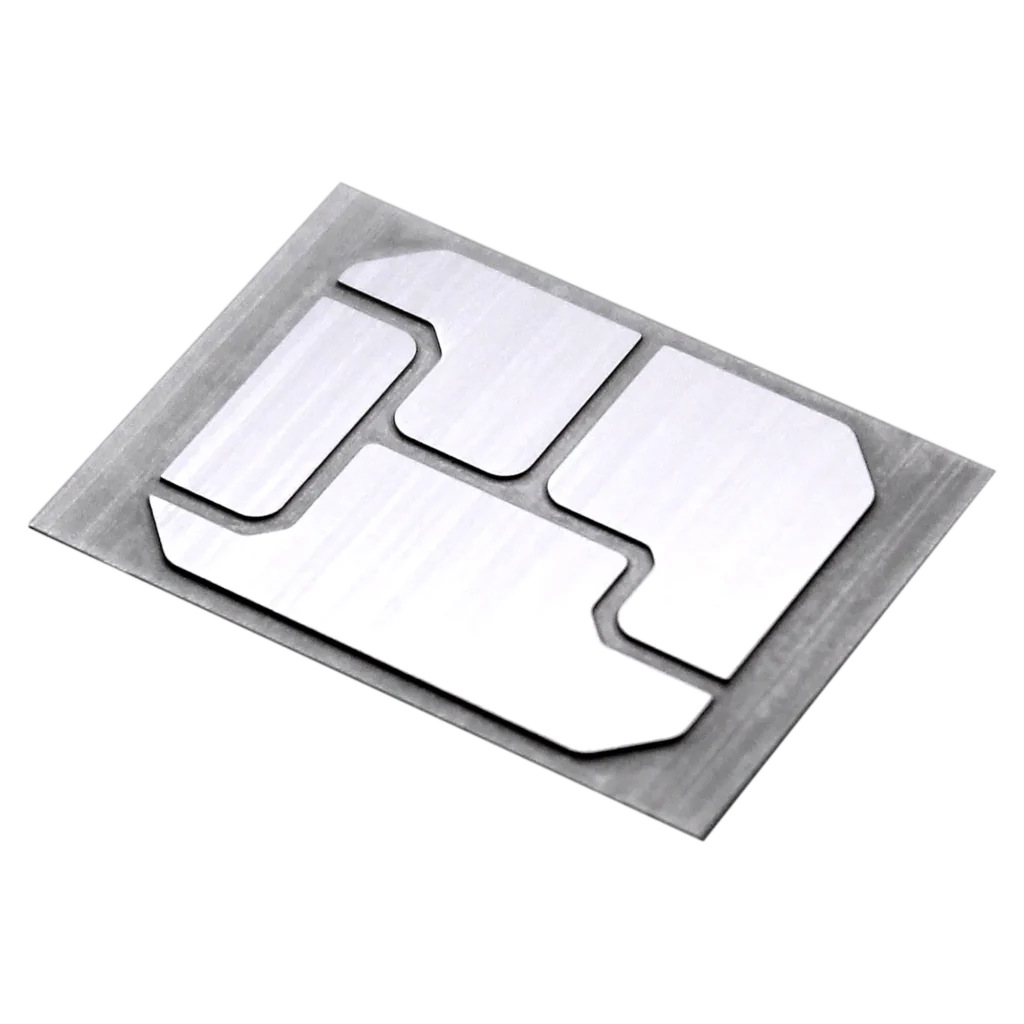

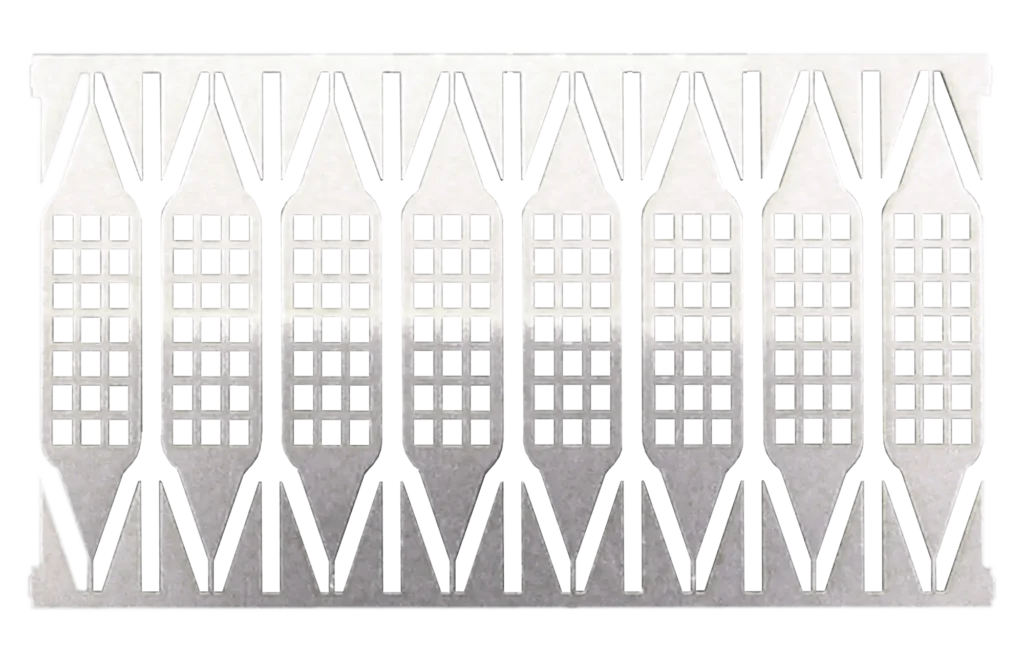

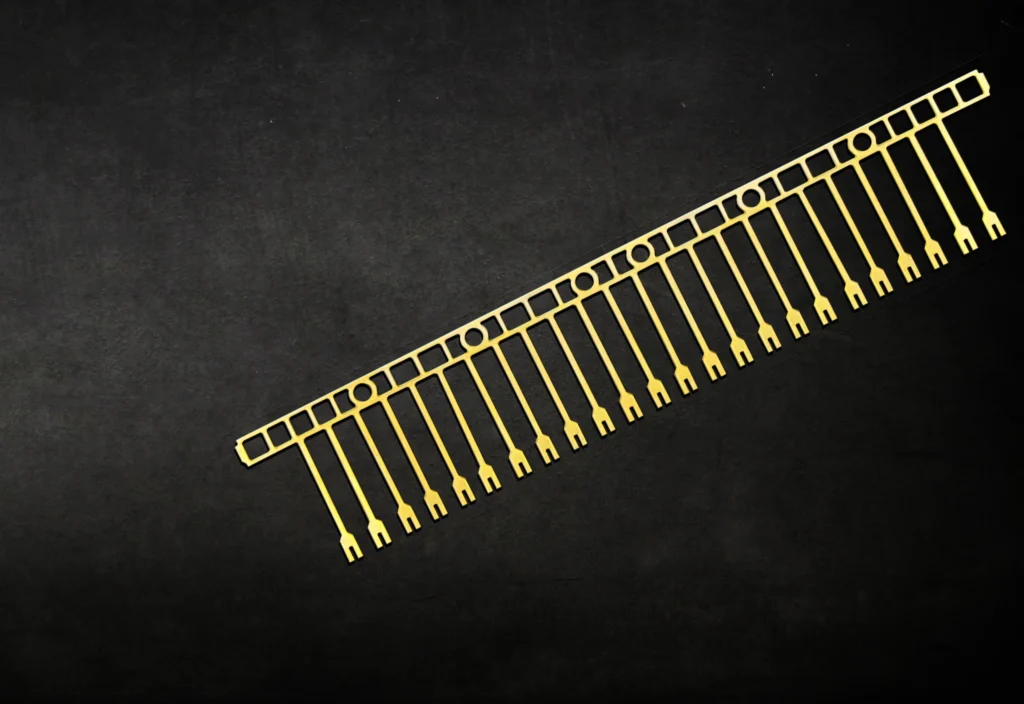

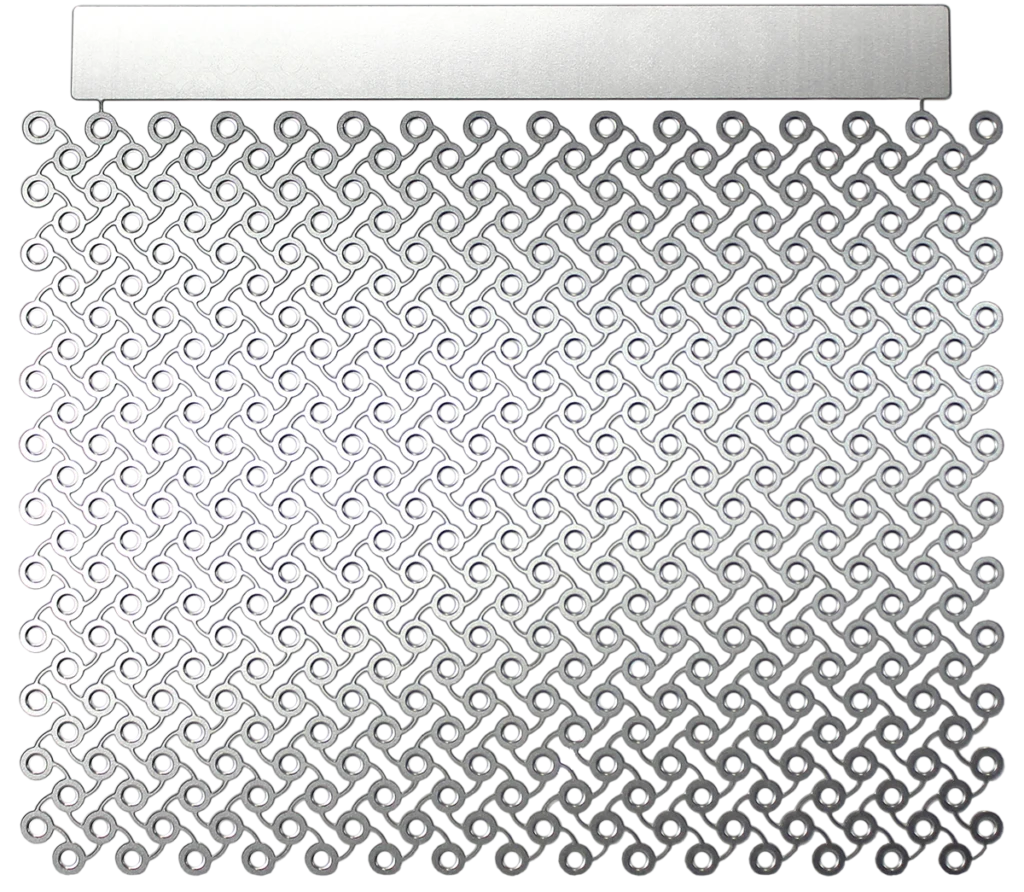

PEI leverages the benefits of stainless steel and photochemically etches precision parts, including filters, fuel cell plates, stators, shims, RF shields, and surgical blades, to name just a few. Our operators feature decades of experience in engineering, manufacturing, and finishing hundreds of parts.

The unique properties of stainless steel make it an ideal choice for dozens of applications across the world’s most important industries.

The high tensile strength of stainless steel allows parts and components to withstand extreme conditions and maintain their form under heavy loads.

Stainless steel’s natural properties make it resistant to rust and corrosion, making it the smart choice for parts in harsh environments.

The metal is easily etched, formed, and machined into various medical, electronics, aerospace, and automotive parts and components.

Engineers pick any one of the various stainless steel alloys and grades to match the demands of their applications.

Please see our Design Guide or contact us for more information about PEI’s additional manufacturing capabilities.

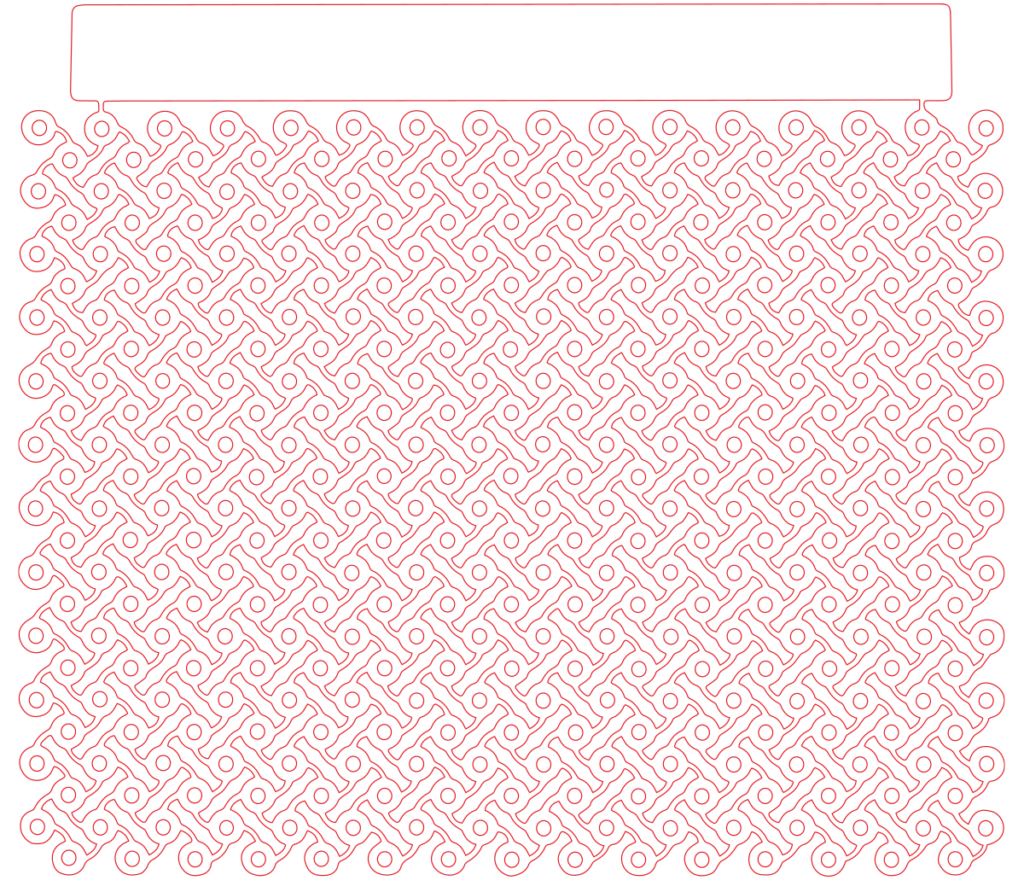

Max 24” x 30”

Minimum 0.0005” — Max 0.200”

Min 0.005” or 110% of material thickness

Minimum 120% of material thickness

Material thickness

Approx. 75% material thickness

DIA + material thickness

± 10% material thickness, no less than ±0.001"

We work with our partners to introduce new ideas and enhanced manufacturing solutions. Our engineers leverage the power of technology and decades of experience to ensure each design and plan will deliver the expected results, whether for the latest in renewable energy or a new life-saving medical technology.

PEI’s commitment to delivering thin metal parts and components utilizing precision photochemical etching dates back decades. We are the world’s leading etcher of titanium and can handle aluminum, beryllium copper, molybdenum, and many other metals. PCE is an ideal manufacturing process for rapid prototyping and high-production runs.

Our precision operators turn thin metal parts into reliable components with meticulous machine and manual forming techniques. PEI’s forming expertise starts at the first step, enabling us to develop highly accurate parts that our team forms to exact standards and specifications.

Protecting precision metal parts from corrosion, wear, and environmental hazards is job number one when applying coatings, finishes, plating, or paint. Finishing applications also offer antibiotic and aesthetic benefits to the parts we produce via photochemical etching.

PEI delivers durable and reliable assembled components found in power-generating, life-saving, and high-technology applications worldwide. Our expert team of engineers and operators team to ensure our partners receive ready-to-implement solutions that will last.

The PEI Quality Assurance team analyzes every thin metal part and component to ensure its precision, accuracy, and durability. Our team uses a combination of technological and manual inspection techniques to check for imperfections before any part or component leaves our facility.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.