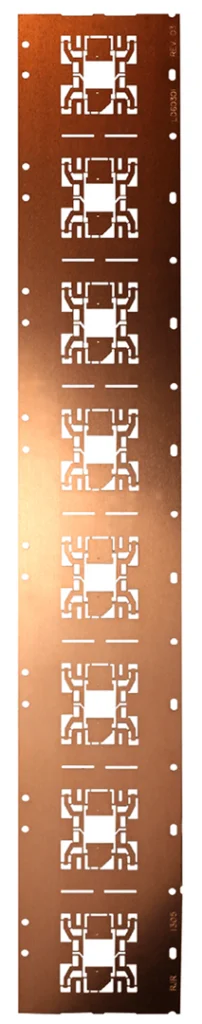

Photofabrication Engineering, Inc. (PEI) is the world’s leader in photochemical etching. We supply titanium bipolar electrolyzer plates, precise thin metal parts, meshes, bus bars, carrier plates, and more.

Our team of engineers, manufacturers, and quality assurance professionals works out of our 40,000-square-foot plant, which features dedicated etching machines, quality assurance tools, and the latest engineering tools.

PEI’s history dates back to 1968, making it one of the manufacturing sector’s most experienced photochemical etching companies. We serve industry leaders in renewable energy, medical, aerospace and defense, and technology and microelectronics.

Our dedication to exceptional customer service, innovative engineering, precise manufacturing, and meticulousness toward quality fuels us every day.

We invite you to explore our range of parts fabricated from a variety of metals in our Product Library and our design guides, plating references guide, and PEI’s Conflict Minerals Reporting Template in our Resource Library.