PEI delivers custom photochemically etched metal components with unmatched accuracy and speed.

As a leading precision etching company, PEI specializes in producing high-quality, burr-free parts with greater precision than traditional machining or stamping.

With over 50 years of experience and expertise, we combine engineering mastery with state-of-the-art process control to create and manufacture thin metal components across a range of material thicknesses, from ultra-thin foils to durable sheet metal.

Our precision chemical machining capabilities produce complex geometries, intricate patterns, and micro features that are suitable for the most demanding applications in aerospace, defense, medical, electronics, and telecom industries.

When you work with PEI, you’re partnering with one of the world’s most experienced etching companies, trusted by engineers to deliver precise, durable, and reliable parts you won’t find anywhere else.

We’re a trusted resource for precision metal parts found in hundreds of components used by industry-leading aerospace manufacturers. PEI’s lightweight, high-tolerance etched parts help improve performance and reduce weight across avionics, sensors, and flight systems.

PEI proudly supports the defense industry, producing mission-critical components that meet stringent military specifications. As an ITAR-registered and ISO-certified U.S.-based etching company, we ensure compliance, traceability, and reliability at every stage.

With ISO-certified processes and deep expertise in biocompatible metals, PEI helps medical innovators design and manufacture safer, stronger, and more precise instruments and implantable devices.

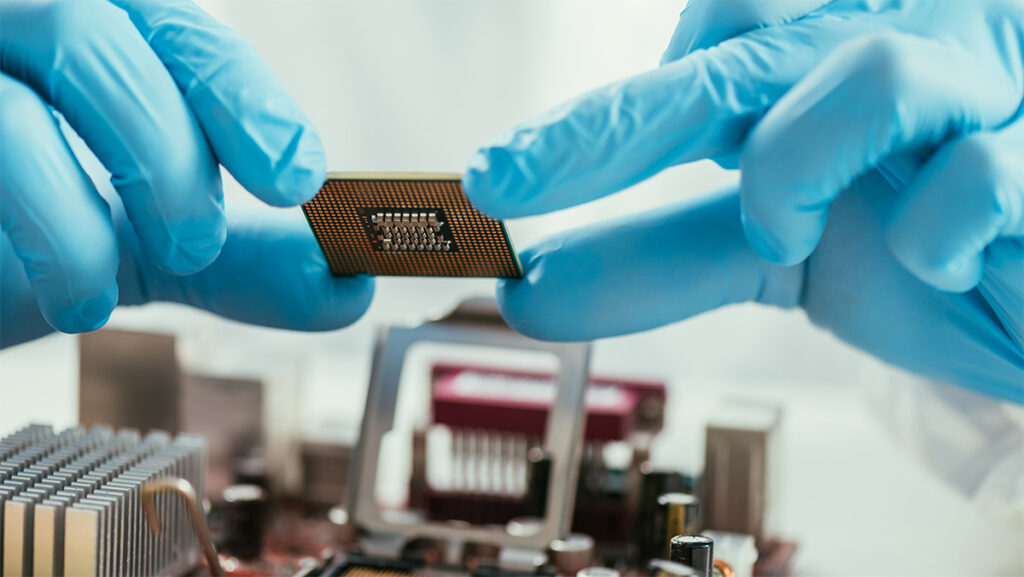

PEI partners with top electronics manufacturers to deliver finely etched components for sensors, connectors, and shielding applications. Our photochemical etching process provides the accuracy and repeatability required for modern miniaturized electronics.

From signal routing to EMI/RFI shielding, our photochemical machining process produces the thin, high-precision parts essential to telecom infrastructure. We specialize in components made from steel, copper, brass, and specialty alloys designed to perform under high-frequency conditions.

For more than five decades, PEI has set the standard for precision etching, offering unparalleled quality, speed, and flexibility.

Our history of innovation and consistency makes us one of the most established names in photochemical etching.

Move from prototype to production quickly with no delays from tooling or setup.

Our chemical etching process supports intricate, high-density geometries that other manufacturing methods can’t achieve.

As a U.S.-based etching company, we maintain full control of production, ensuring security, traceability, and compliance for mission-critical projects.

PEI’s photochemical etching process begins with a precisely applied photoresist pattern on metal sheets. Using controlled acid etching, we dissolve unprotected areas to produce accurate, burr-free parts that maintain full material integrity. This non-contact subtractive process ensures consistent material thickness, tight tolerances, and smooth edges, making it ideal for delicate or high-performance components.

Our in-house expertise spans a wide range of sheet metal materials, including stainless steel, copper, brass, titanium, nickel, and specialty alloys. Our precision process achieves tolerances within ±0.0005”, giving engineers the ability to create complex designs without sacrificing structural performance or reliability.

Lightweight, burr-free shields that block electromagnetic interference in sensitive electronics.

When accuracy, speed, and reliability matter, PEI is the precision etching company trusted by engineers worldwide. From rapid prototyping to full-scale production, our photochemical machining expertise ensures you get precisely what your project demands, on time, every time.