PEI delivers advanced diffusion bonding solutions for high-precision components across aerospace, medical, defense, electronics, and energy systems.

Our process creates ultra-reliable, stress-free, diffusion-bonded joints that maintain the full properties of the base metal, making them ideal for mission-critical, multilayer assemblies involving dissimilar materials.

Diffusion bonding is a solid-state diffusion bonding process that joins layers of thin metal sheets together using elevated temperature and pressure without the use of adhesives, filler materials, or mechanical fasteners. Unlike welding or brazing, diffusion bonding occurs when atoms migrate across clean, metal-to-metal interfaces under tightly controlled conditions. The result is a seamless joint that retains the full mechanical and chemical integrity of the parent materials.

Typically performed in a vacuum or inert atmosphere, the process involves heating the stacked metal layers to approximately 50–80% of the base material’s melting point and applying pressure to initiate atomic diffusion.

Because it does not rely on molten phases, diffusion bonding is also a valuable alternative to transient liquid phase bonding methods when working with thin components or dissimilar alloys.

Diffusion bonding offers several advantages over traditional joining methods:

Whether you’re building microfluidic channels or lightweight structural assemblies, diffusion bonding is ideal when your design demands structural integrity, dimensional stability, and long-term durability.

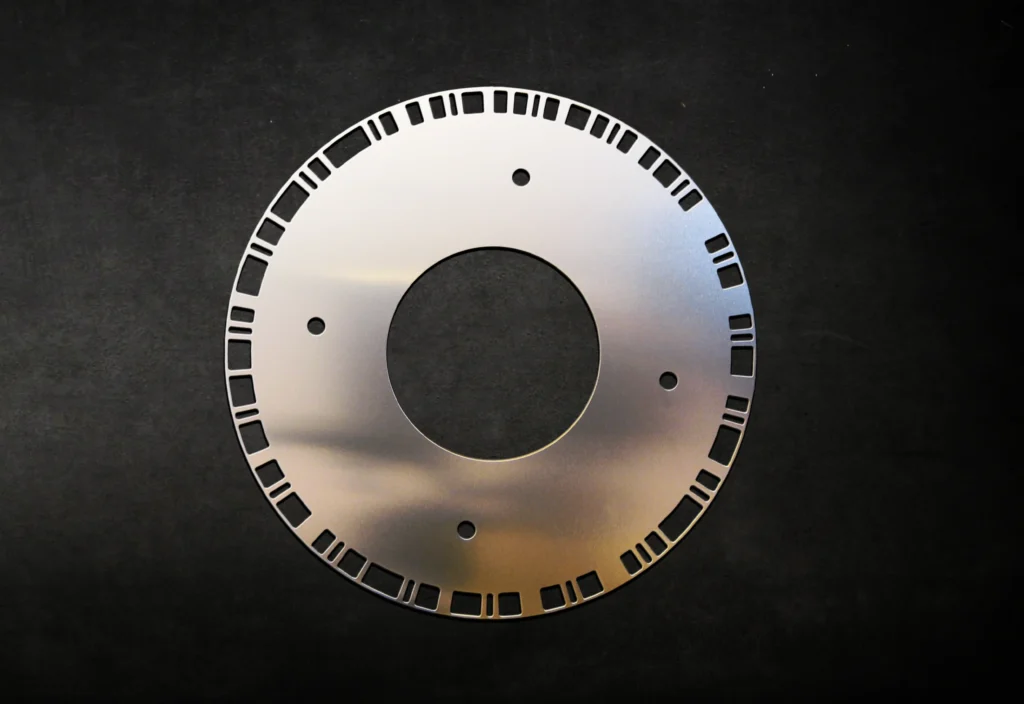

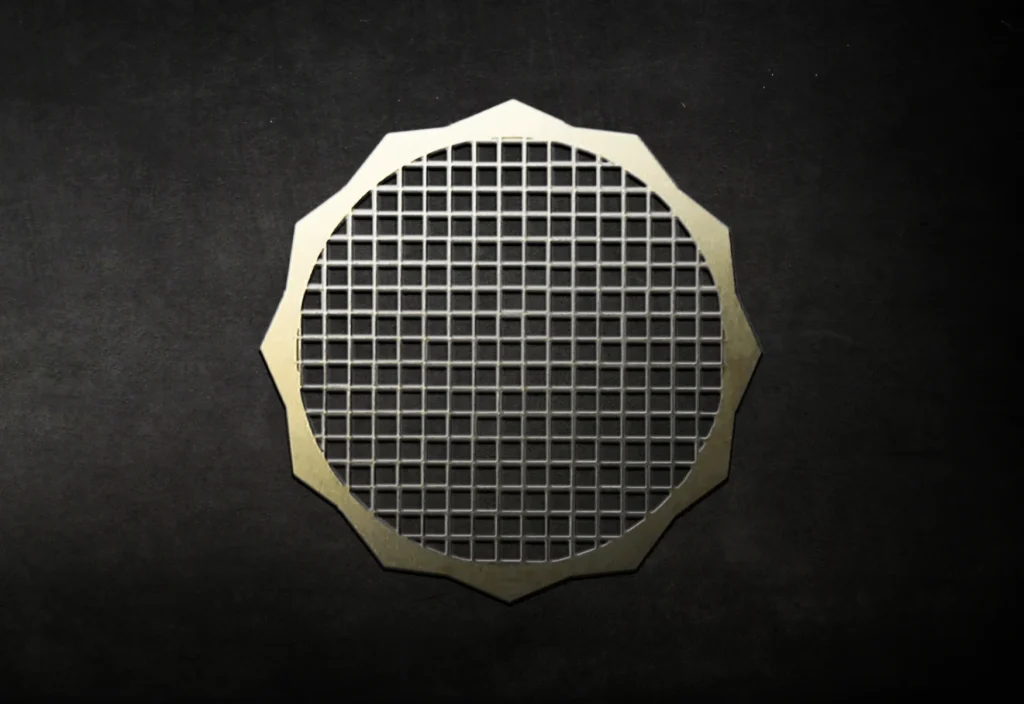

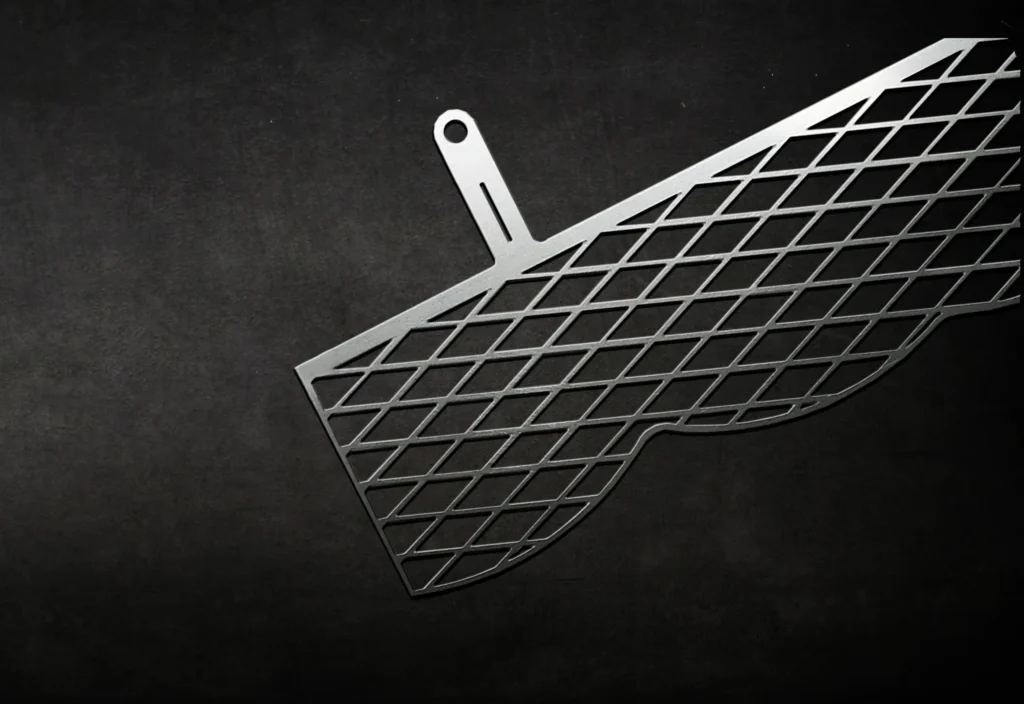

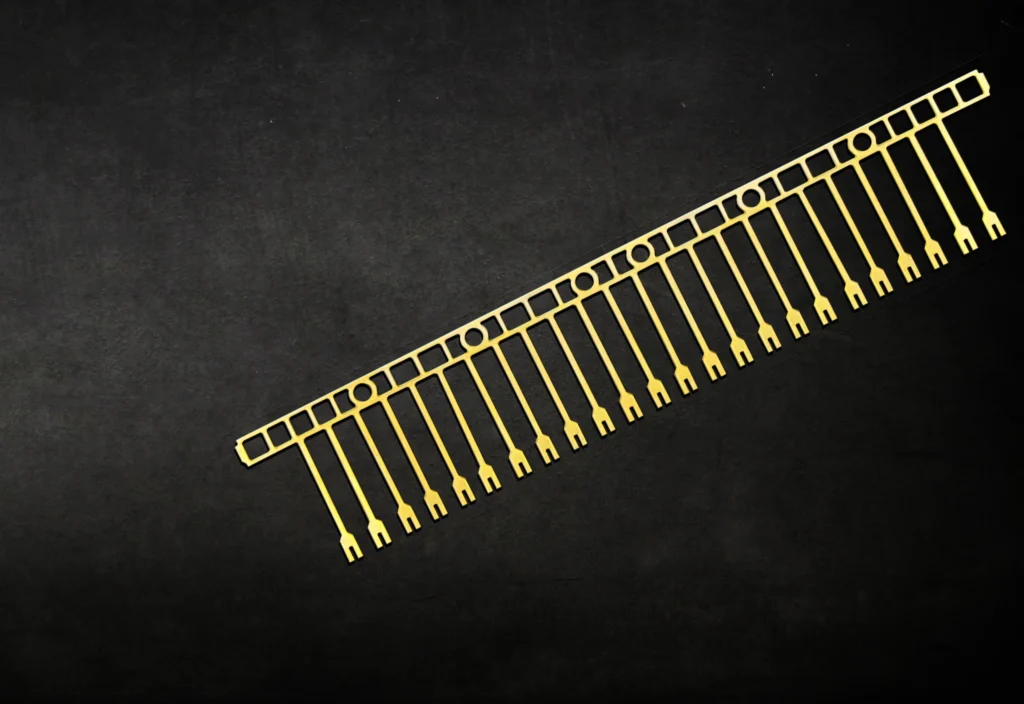

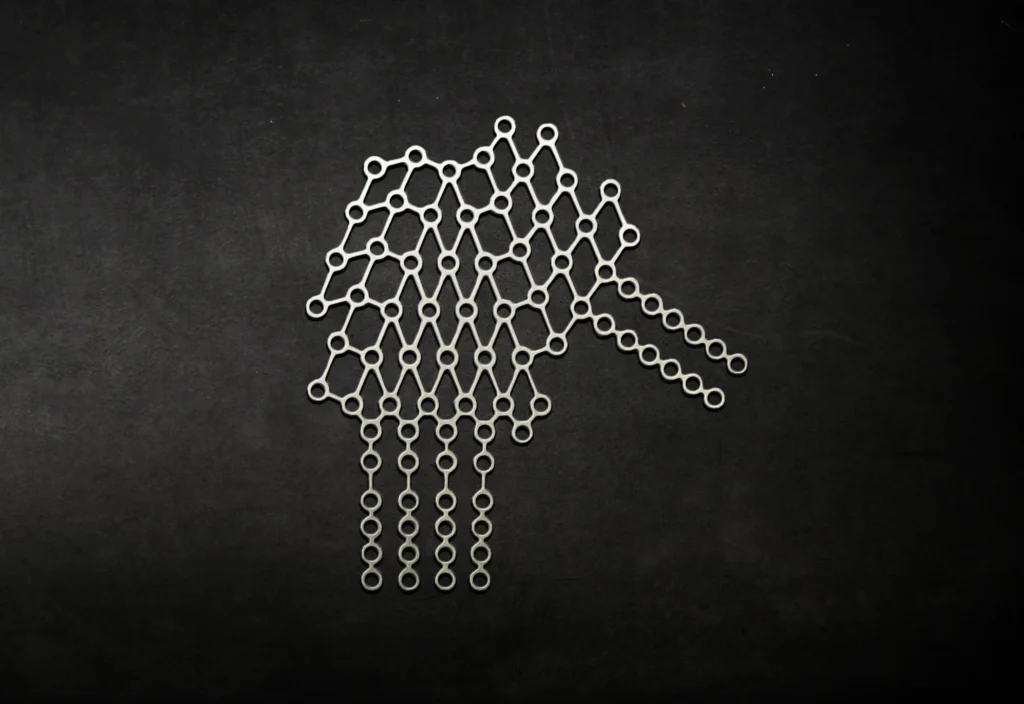

At PEI, our strength lies in our integrated manufacturing capabilities. We combine diffusion bonding with photochemical etching to produce complex multilayer assemblies with tight-tolerance internal features ideal for applications in aerospace, medical, and advanced electronics, where precision and reliability are critical.

As a U.S.-based, ITAR-compliant manufacturer, we offer a secure and responsive production environment tailored to the needs of defense and aerospace clients. With a proven track record and a precision-controlled facility certified to ISO 9001 and AS9100D, we ensure that every component meets the highest standards of quality, consistency, and compliance.

Our diffusion bonding method is engineered for consistency, precision, and repeatability:

This precision diffusion bonding method allows us to produce high-quality joints even in dissimilar metals, without thermal damage or warping.

Our diffusion bonding capabilities support a broad range of high-performance metals, including:

Our precision process allows us to produce high-quality joints in materials that are notoriously challenging for traditional joining processes, making it particularly useful in regulated industries with exacting specs.

Key Applications of Diffusion Bonding

PEI’s diffusion bonding services are trusted across a wide spectrum of critical applications where performance and precision are paramount:

These sectors often involve dissimilar materials, extremely thin metals, and complex internal features that require a joining process with high bond integrity and zero distortion.

Contact PEI’s diffusion bonding experts to explore how we can help you engineer stronger, lighter, and more precise components.

PEI’s long history of meeting and exceeding industry standards and customer expectations began in 1968. For over 50 years, we’ve kept quality assurance at the forefront of our work by training our manufacturing teams, maintaining our equipment, and establishing rigorous internal controls. PEI holds several certifications, including ISO9001:2015, AS9100:2016, and ITAR. We adhere to MIL-STD-45662, MIL-STD-105, and ANSI/ASQC Z1.4 quality standards.