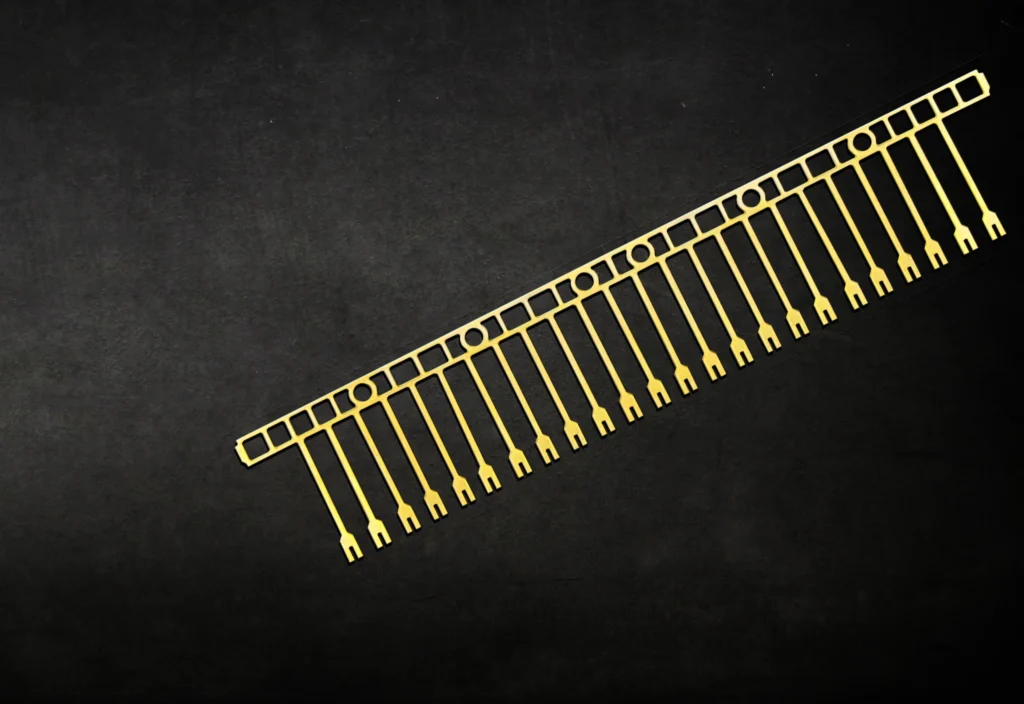

PEI is uniquely equipped to photochemically etch and manufacture precision components from Inconel, a high-performance nickel-chromium superalloy known for its strength, corrosion resistance, and stability in some of the world’s harshest operating conditions.

Inconel is ideal for applications involving high temperatures, mechanical stress, or exposure to aggressive chemicals, making it a preferred material for aerospace, defense, energy, and industrial electronics.

Inconel offers an exceptional combination of mechanical properties, oxidation resistance, and temperature stability. These qualities make it a go-to material when failure is not an option, whether it’s inside a jet engine or in a corrosive chemical processing environment.

Key properties include:

Inconel offers remarkable mechanical strength, even at elevated temperatures exceeding 1000°F (538°C). This makes it ideal for high-heat environments such as jet engines, exhaust systems, and industrial turbines.

With exceptional resistance to oxidation, acids, and chloride-induced corrosion, Inconel performs reliably in aggressive environments — including chemical plants, offshore platforms, and marine applications.

Engineered to withstand repeated stress and extreme temperature shifts, Inconel maintains structural integrity over long operational lifespans—perfect for aerospace, defense, and energy systems where durability is essential.

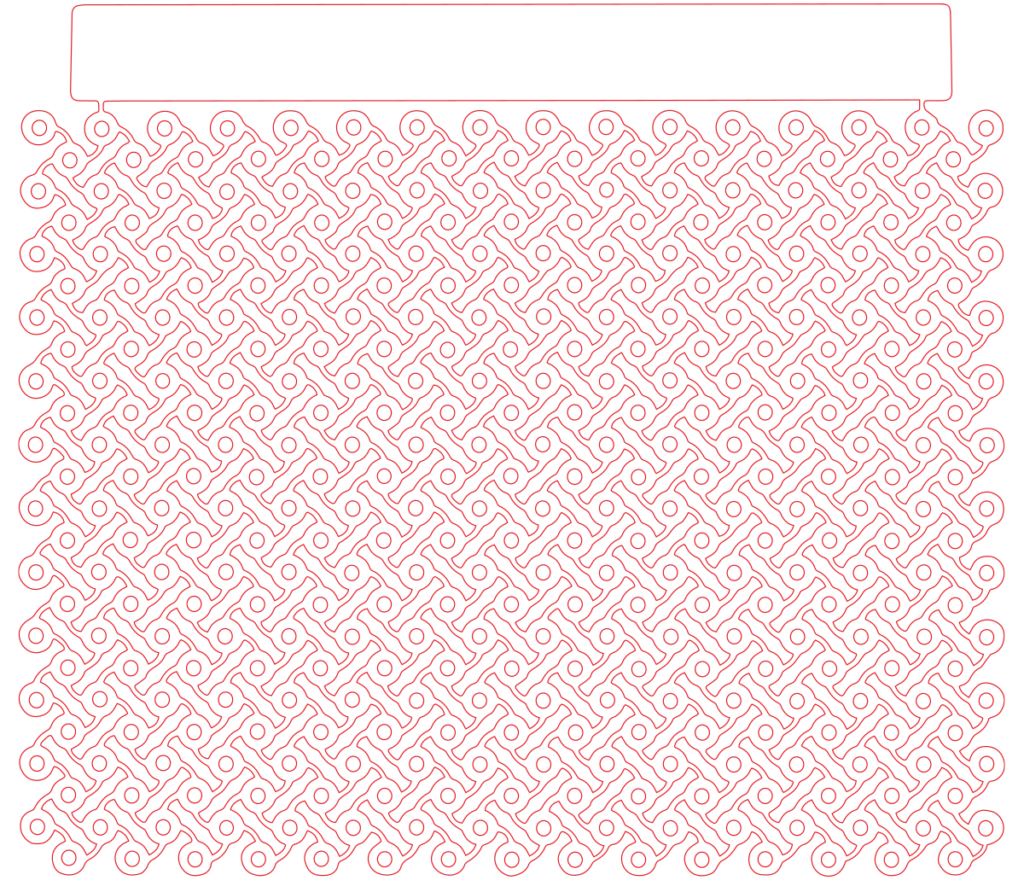

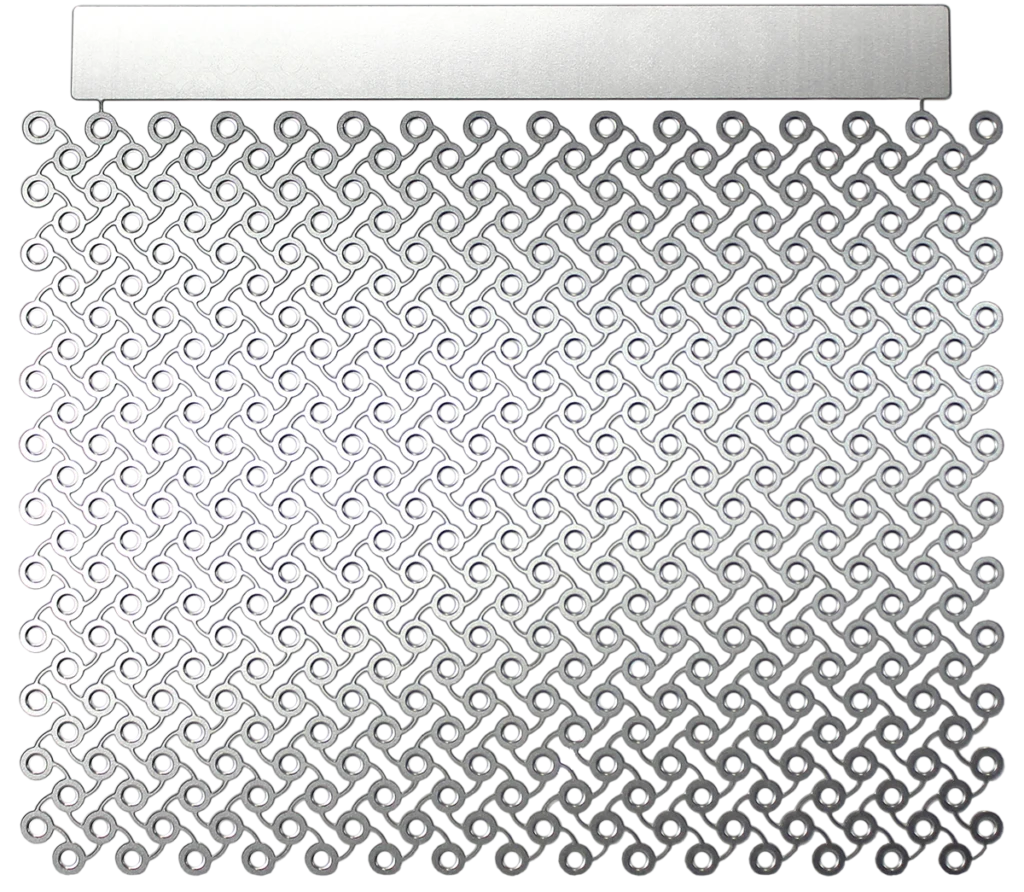

While Inconel is difficult to machine through traditional subtractive methods, photochemical etching provides a burr-free, heat-free alternative ideal for thin, complex, or sensitive parts—especially those used across a wide temperature range.

Advantages of the chemical etching process:

Combined with custom tooling and rapid prototyping capabilities, PEI’s chemical etching solution supports flexible production from prototype to volume scale—delivering superior results for industries that demand reliability and repeatability.

Key properties include:

We specialize in high-performance Inconel etching — from prototypes to full-scale production runs. Please see our Design Guide or Contact Us for more information about our additional manufacturing capabilities.

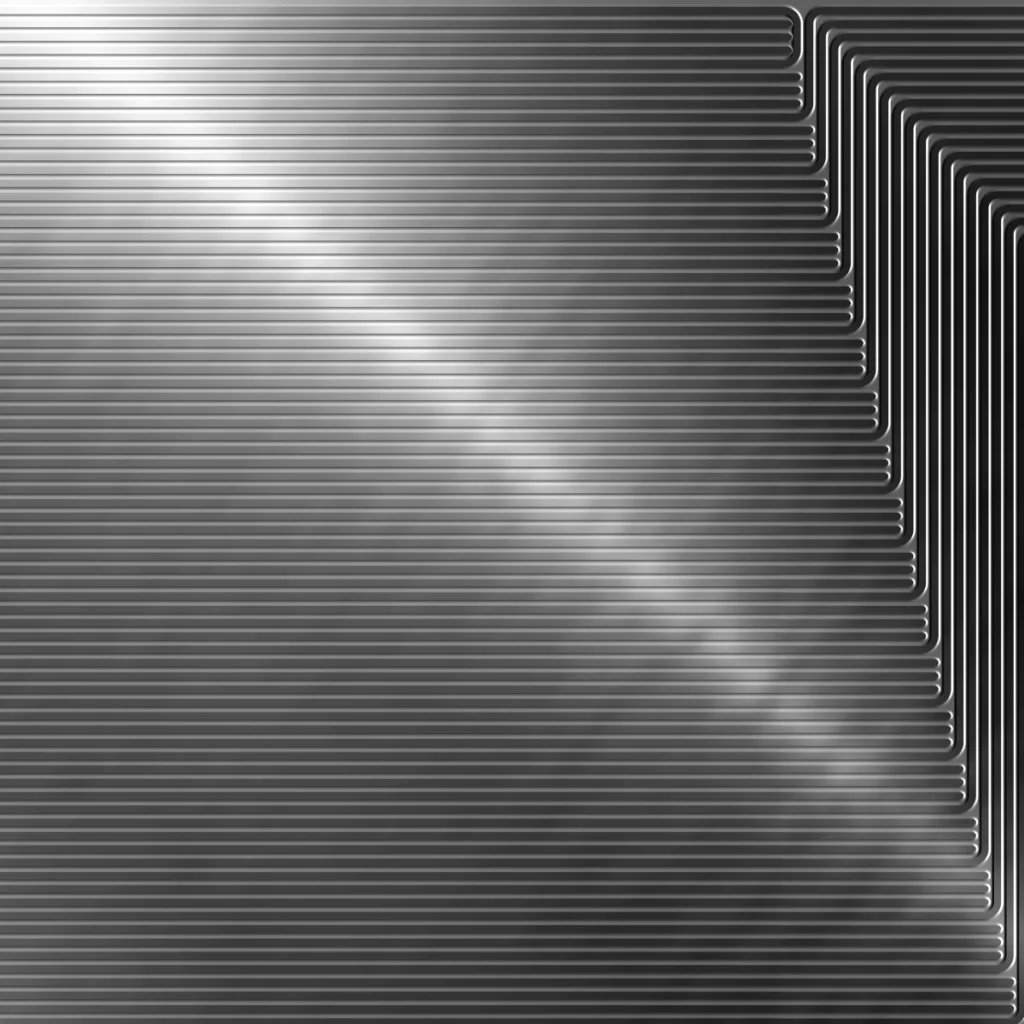

Our proprietary Eco-Chem™ photochemical etching process is engineered for precision, safety, and sustainability.

Unlike mechanical or laser cutting, our process does not introduce stress or heat distortion.

We use proprietary, RoHS-compliant etchants (including hydrofluoric acid) designed to minimize environmental impact.

Our proven process means no heat-affected zones or micro-cracks, maintaining the full strength of titanium.

We offer short lead times for prototypes and scalable production capacity.

Our engineers collaborate closely with you to optimize designs for manufacturability and cost efficiency.

Our facilities adhere to rigorous handling protocols and employ advanced containment systems to ensure maximum safety during chemical etching operations.

As an industry leader in the production of thin metal parts, PEI has developed proprietary processes that ensure exceptional results when working with Inconel.

Our process capabilities include:

PEI is AS9100D, ISO 9001, and ITAR certified, offering full traceability and consistent quality assurance for mission-critical applications.

Inconel’s exceptional strength, heat resistance, and corrosion performance make it a vital material across industries where failure is not an option. PEI manufactures precision-etched Inconel parts that support mission-critical performance in the most demanding environments.

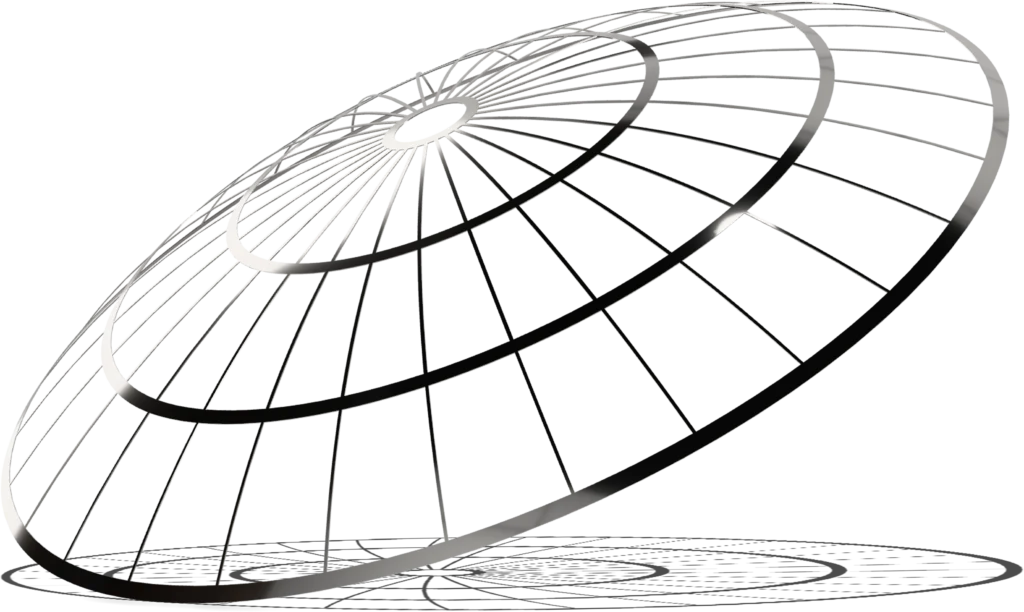

Used in turbine engine components, exhaust systems, and EMI/RF shielding, Heat Exchangers, Inconel withstands extreme temperatures and stress cycles found in flight-critical applications.

Ideal for guided systems, high-temperature shielding, and structural supports, Heat Exchangers, Inconel delivers the durability and reliability required in defense platforms and secure systems.

From high-temperature gas turbines to components used in corrosive chemical processing, Inconel is trusted for its ability to withstand aggressive industrial conditions.

Compact, corrosion- and heat-resistant Inconel enclosures and components protect sensitive electronics in high-performance or high-temperature settings.

Whether you’re working with Inconel 600 or another superalloy grade, PEI helps you achieve optimal performance through precision manufacturing.

The reliability of your end product starts with the precision of your parts. With deep material expertise, advanced technology, and decades of experience, PEI delivers Inconel components that meet the most demanding requirements without compromise.

We work with our partners to introduce new ideas and enhanced manufacturing solutions. Our engineers leverage the power of technology and decades of experience to ensure each design and plan will deliver the expected results, whether for the latest in renewable energy or a new life-saving medical technology.

PEI’s commitment to delivering thin metal parts and components utilizing precision photochemical etching dates back decades. We are the world’s leading etcher of titanium and can handle aluminum, beryllium copper, molybdenum, and many other metals. PCE is an ideal manufacturing process for rapid prototyping and high-production runs.

Our precision operators turn thin metal parts into reliable components with meticulous machine and manual forming techniques. PEI’s forming expertise starts at the first step, enabling us to develop highly accurate parts that our team forms to exact standards and specifications.

Protecting precision metal parts from corrosion, wear, and environmental hazards is job number one when applying coatings, finishes, plating, or paint. Finishing applications also offer antibiotic and aesthetic benefits to the parts we produce via photochemical etching.

PEI delivers durable and reliable assembled components found in power-generating, life-saving, and high-technology applications worldwide. Our expert team of engineers and operators team to ensure our partners receive ready-to-implement solutions that will last.

The PEI Quality Assurance team analyzes every thin metal part and component to ensure its precision, accuracy, and durability. Our team uses a combination of technological and manual inspection techniques to check for imperfections before any part or component leaves our facility.

Industries and technologies evolve when people work together to push boundaries and uncover new solutions. For over 50 years, we’ve stood shoulder to shoulder as leading companies across every market sector push forward with revolutionary changes that change the world. We are ready to share and leverage knowledge and expertise to collaborate with our customers for mutual success.