Modern engineering challenges are rarely solved with a single manufacturing method. As components shrink, tolerances tighten, and performance demands rise, traditional manufacturing methods often fall short. To meet these evolving requirements, engineers are increasingly turning to hybrid manufacturing— a strategy that combines multiple processes to achieve results no single method can deliver alone.

One of the most powerful hybrid approaches in precision metal manufacturing is laser cutting and etching. When used together, these two processes allow engineers to balance speed, precision, geometry, and material integrity in ways that fundamentally change what’s possible in thin‑metal part design.

At Photofabrication Engineering, Inc. (PEI), laser cutting and photochemical etching are not competing technologies but complementary tools. By offering both processes in‑house and designing workflows that intentionally combine them, PEI helps engineers push boundaries in key industries like aerospace, electronics, defense, photonics, and medical manufacturing.

In this article, we explore why engineers combine laser cutting and chemical etching, how hybrid manufacturing delivers superior results, and why PEI’s integrated approach gives customers a measurable advantage from prototype through production.

Why Hybrid Manufacturing Matters Today

Hybrid manufacturing reflects a broader shift in engineering priorities. Modern parts must be lighter, thinner, more precise, and more reliable, often all at once. Traditional manufacturing methods, while proven, struggle to meet these requirements alone.

Laser cutting excels at producing fast, accurate outer profiles. Chemical etching excels at producing fine internal features with zero mechanical stress. Used independently, each method has limits. Used together, they unlock new levels of performance, consistency, and design freedom.

Engineers no longer ask, “Which process should I use?”

They ask, “How do I combine processes to get the best result?”

That question is at the heart of PEI’s hybrid manufacturing philosophy.

Why Combine Laser Cutting and Etching?

Laser Cutting: Precision and Speed Where It Counts

Laser cutting is ideal for defining external geometries, trimming outlines, and producing rapid prototypes. A focused laser beam can quickly and repeatably cut complex outer shapes without tooling.

Because the laser cutting process is digitally driven, engineers can move from CAD to part in days rather than weeks. This makes laser cutting especially valuable during early design iterations or when turnaround time is critical.

However, laser cutting alone is not ideal for everything. Extremely fine internal features, tight spacing between apertures, and thin foils can introduce heat‑affected zones, micro‑burrs, or edge irregularities when cut solely with a high-powered laser beam.

Chemical Etching: Precision Without Stress

Chemical etching removes material through controlled chemistry rather than force or heat. The etching process produces perfectly burr‑free edges, uniform internal features, and consistent thickness, regardless of complexity.

Etching is especially effective for:

- Dense internal patterns

- Fine slots and apertures

- Thin metals and foils

- Stress‑sensitive components

Because material is removed evenly from both sides, etched features remain flat and dimensionally stable, even in ultra‑thin sections.

Together: Maximum Precision Without Compromise

When combined, laser cutting and etching give engineers the best of both worlds:

- Laser cutting defines fast, precise outer profiles

- Etching refines internal geometry and fine details

- Material properties remain intact

- Secondary deburring or finishing is often eliminated

At PEI, engineers routinely design parts that leverage two processes intentionally, using each exactly where it performs best.

The Advantages of Hybrid Manufacturing

Hybrid manufacturing is not about redundancy; it’s about optimization. Here is why more and more engineers are choosing the hybrid model:

Complex Geometry Without Tradeoffs

By combining processes, engineers can create parts with:

- Sharp external profiles

- Dense internal patterns

- Tight spacing between features

- Consistent dimensional accuracy

This is especially important for intricate designs that would be distorted, warped, or prohibitively expensive using a single method.

Superior Results in Thin and Difficult Metals

Many precision applications involve various materials that are difficult to machine mechanically, including ultra‑thin foils and specialty alloys. Hybrid workflows allow PEI to adapt processing strategies based on material behavior rather than forcing one method to do everything.

This flexibility is critical when working across different materials with varying thermal and mechanical properties.

Reduced Secondary Operations

Mechanical cutting often requires deburring, polishing, or stress relief. Chemical etching does not. When etching is used for internal features and laser cutting for outlines, many secondary steps disappear, reducing cost, risk, and lead time.

Optimized Cost and Lead Time

Laser cutting is fast and flexible. Etching is precise and repeatable. Together, they create an affordable option for complex parts that would otherwise require expensive tooling or multi‑step machining.

This is why hybrid manufacturing is rapidly becoming the preferred model across high‑precision industrial applications.

Key Applications of Laser Cutting and Etching

Hybrid manufacturing supports a wide range of advanced technologies where precision, reliability, and performance are non‑negotiable.

Medical Devices

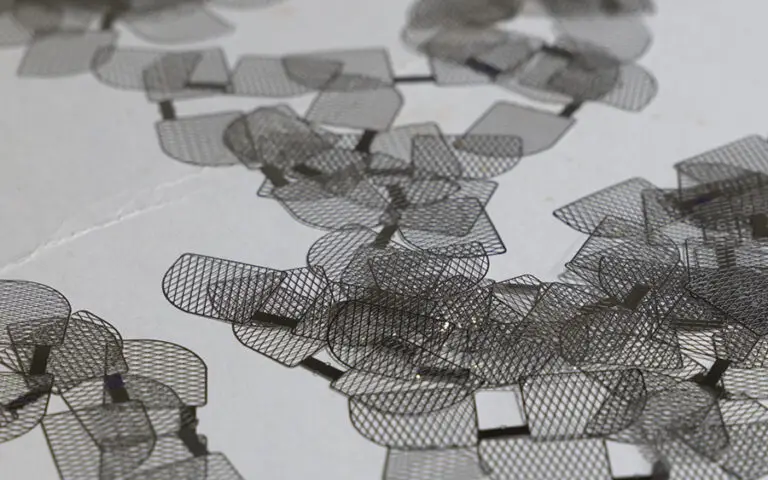

Medical components often combine thin metals, fine features, and strict cleanliness requirements. Hybrid manufacturing enables:

- Catheter components with laser‑cut outlines and etched internal features

- Stents and filters with burr‑free apertures

- Precision medical screens with consistent geometry

Laser cutting defines form. Etching refines function.

Aerospace Systems

Aerospace applications demand lightweight, high‑performance components with absolute dimensional consistency. Hybrid manufacturing is ideal for:

- Light shielding

- Fuel injector screens

- Microfluidic flow control parts

By combining processes, PEI delivers aerospace parts that maintain strength without distortion.

Photonics and Optical Systems

Photonics components require extreme precision to control light paths and beam alignment. Hybrid manufacturing enables:

- Optical apertures

- Light‑control grids

- Precision alignment shims

The ability to control both external and internal geometry is critical in these systems.

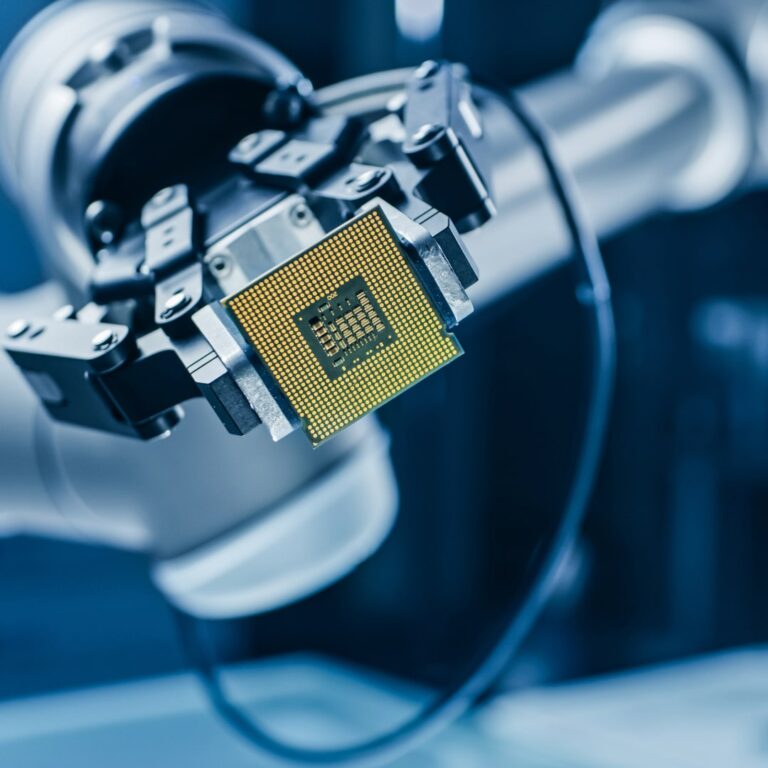

Electronics and RF Systems

Electronics benefit from hybrid manufacturing, where electrical performance depends on geometry. Typical applications include:

- RF shields

- Connector plates

- Precision shims and spacers

Etched features ensure uniform signal behavior, while laser cutting maintains clean external profiles.

In‑House Efficiency: The PEI Difference

Hybrid manufacturing only works when processes are tightly integrated. At PEI, laser cutting and etching are performed under one roof, eliminating delays, misalignment, and cross‑vendor risk.

By keeping everything in‑house, customers gain access to a single supplier and a single quality system. For customers, this means:

- Turnaround times are faster

- Quality control is consistent

- Registration between processes is precise

- Accountability is clear

There is no handoff risk and no guesswork between suppliers.

PEI’s in-house efficiency also offers customers unmatched prototype-to-production flexibility. It allows engineers to prototype quickly using laser cutting, refine details through etching, and then scale directly into production without redesign.

This flexibility is supported by our collaborative design optimization process. Our engineers work closely with customers to evaluate which features are best suited for laser cutting and which benefit from chemical etching. We also help determine the optimal sequencing of each step to maximize precision, efficiency, and material integrity.

By integrating design support early in the development cycle, we ensure the combined laser cutting and etching workflow performs as intended from first article to full-scale production.

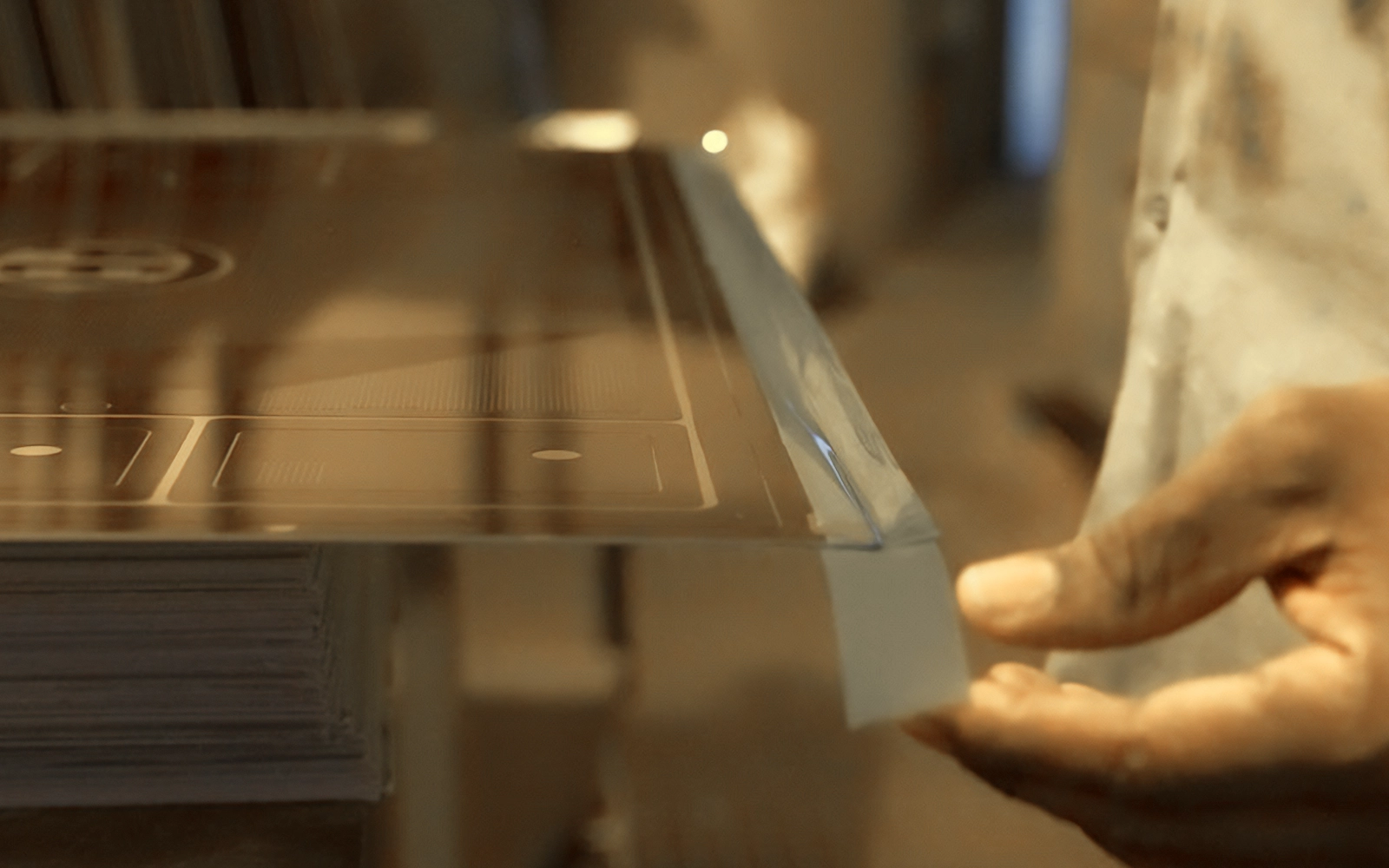

PEI’s Precision Laser Cutting Machines and Process

PEI’s laser cutting capabilities are engineered for precision, flexibility, and repeatability.

Our state‑of‑the‑art laser systems support both cutting and marking, offering a cleaner, more precise alternative to traditional plasma or mechanical methods.

Our advanced laser cutting equipment includes:

- IPG 4kW Fiber Laser

This system supports high‑speed cutting across a wide range of metal thicknesses and alloys using a modern fiber laser architecture. - Keyence Fiber Laser Marking System

Used for permanent identification, traceability, and compliance through advanced laser marking methods. This includes serial numbers, barcodes, and QR codes. - Optical Alignment System

Enables precise registration between etched and laser‑cut features, ensuring perfect alignment across processes.

Unlike older systems, our modern laser machine technology delivers tighter tolerances, finer edge quality, and greater design flexibility than legacy equipment such as YAG systems or mechanical cutters.

What About Laser Engraving?

While laser cutting and etching define part geometry, laser engraving plays a critical role in traceability and identification. Using focused laser processes, PEI can apply high-contrast, permanent markings, such as serial numbers, barcodes, and logos, directly to the material surface without altering part dimensions.

When the beam hits the surface, controlled laser power vaporizes just enough material to create a crisp, durable mark suitable for regulatory compliance and part tracking. This technique supports a wide range of metals and alloys and integrates seamlessly into PEI’s hybrid manufacturing workflow, ensuring consistent results across both simple and complex components.

Hybrid Laser Etching: The Future

As component requirements continue to tighten, hybrid manufacturing will only become more essential.

Emerging technologies demand:

- Smaller features

- Higher precision

- Greater material integrity

- Faster development cycles

No single process can meet all of these demands alone.

Hybrid manufacturing, especially the combination of laser cutting and chemical etching, represents the future of precision metal fabrication. It allows engineers to design without compromise and manufacture with confidence.

At PEI, this future is already in production.

Precision Without Compromise

Combining laser cutting and chemical etching allows engineers to achieve maximum precision, geometric complexity, and material integrity in parts that would be difficult or impossible to manufacture using a single method.

From medical devices to aerospace systems, photonics to electronics, hybrid manufacturing enables smarter designs, faster timelines, and more reliable results.

By offering both capabilities in‑house, PEI empowers engineers to push boundaries, reduce risk, and bring high‑precision components to life.

By leveraging both processes, we can deliver parts with complex geometries, minimal distortion, and precise overlays, all without the need for multiple vendors. Our optical registration ensures perfect alignment, reducing turnaround time and ensuring consistent quality.

The result? A complete metal fabrication solution with greater design freedom, faster prototyping, and reduced costs.

Ready to Push Precision Further?

Talk to our engineers about combining laser cutting and etching for your next high‑precision project.