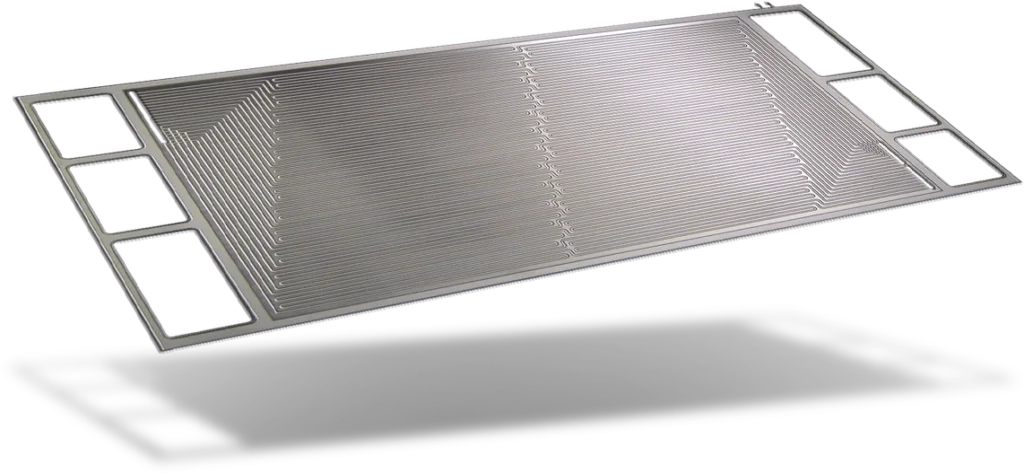

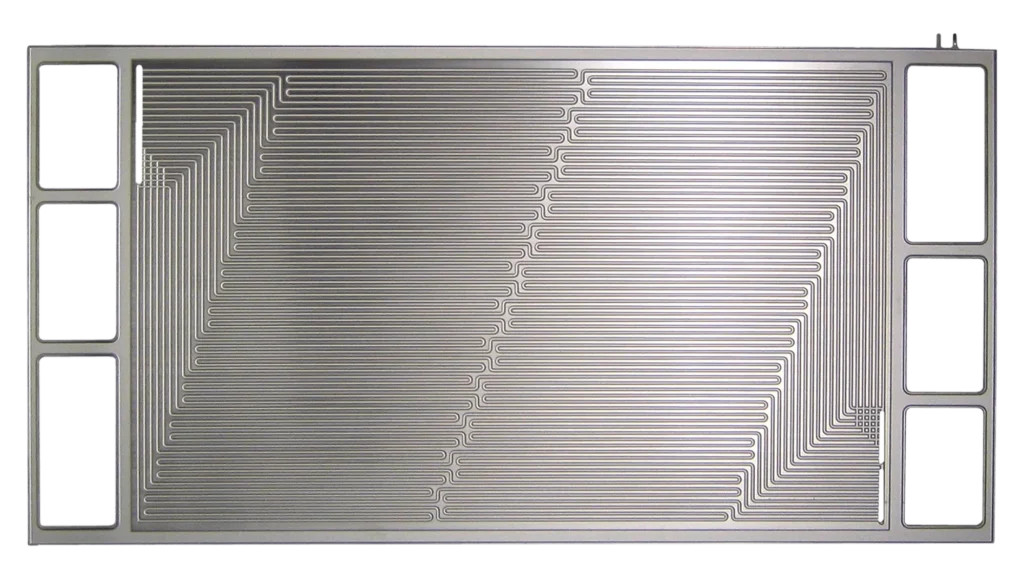

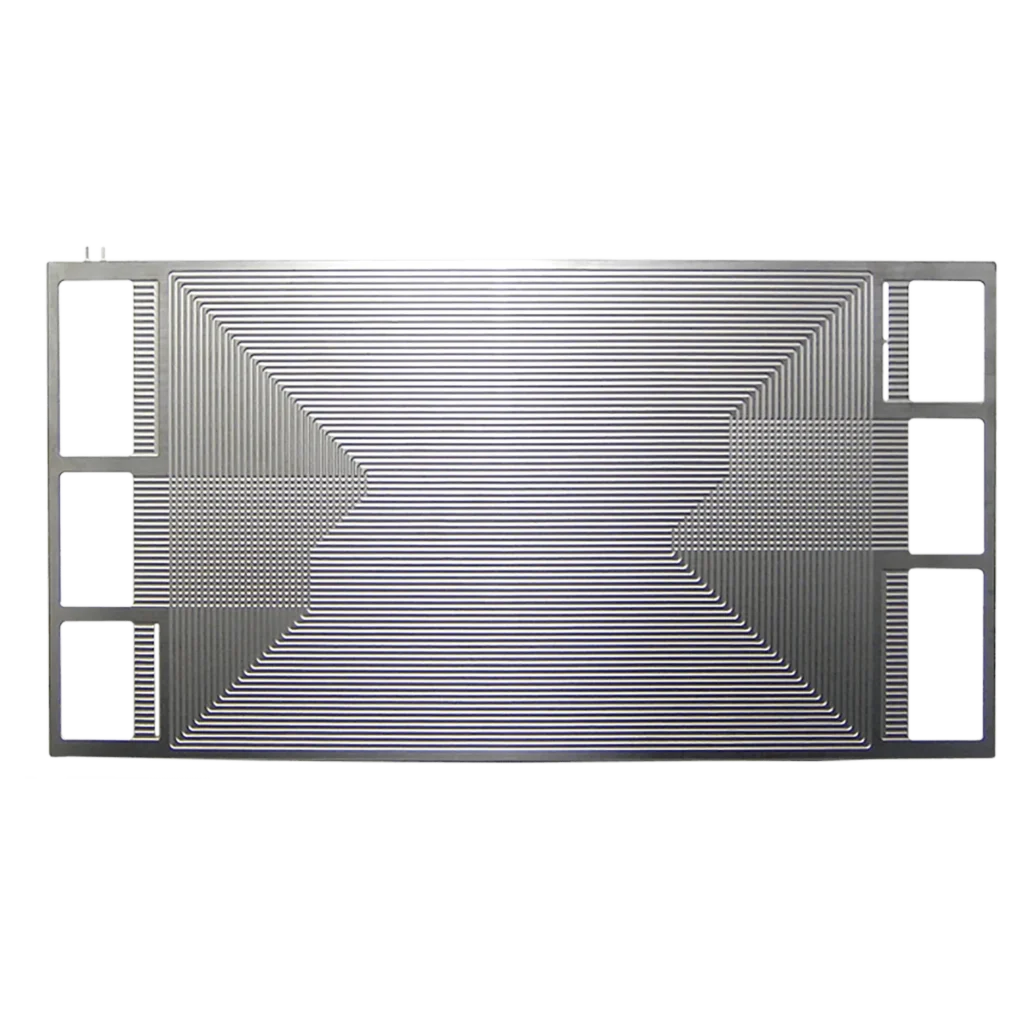

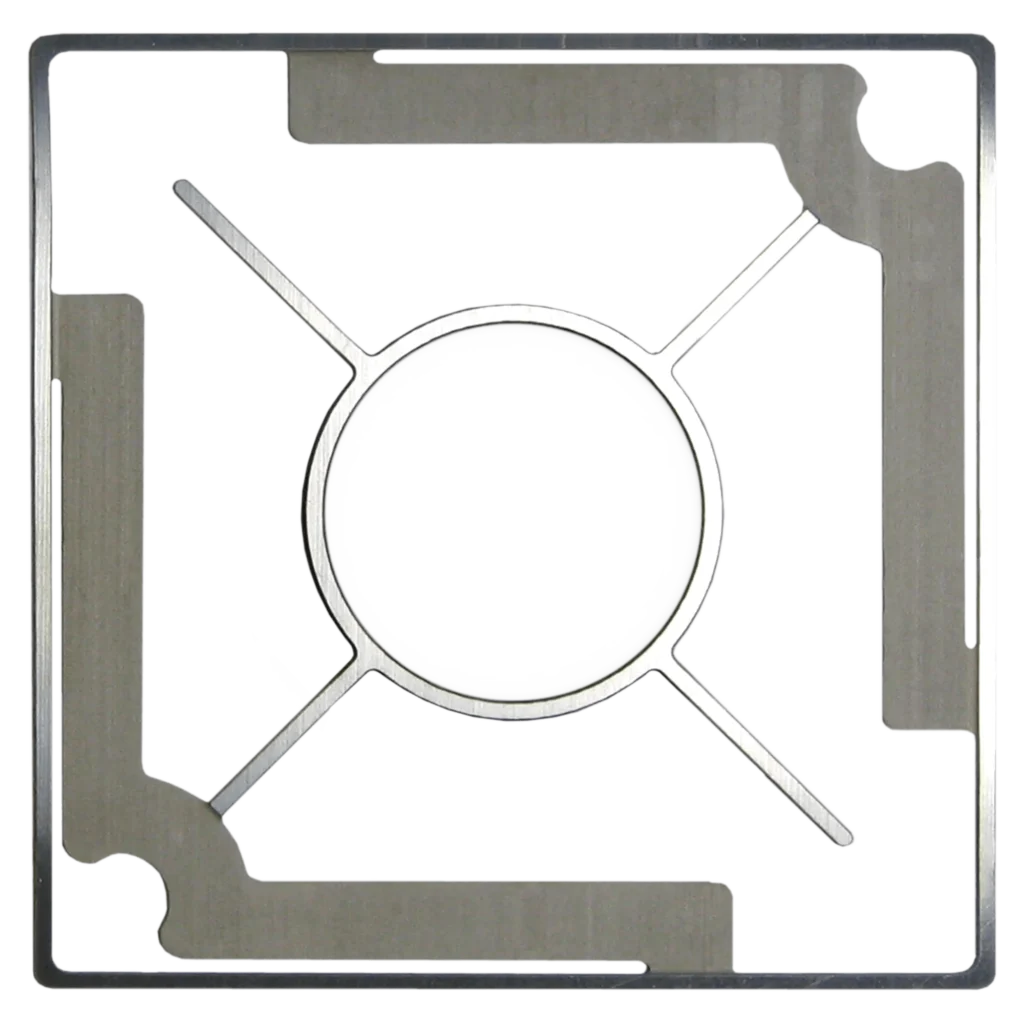

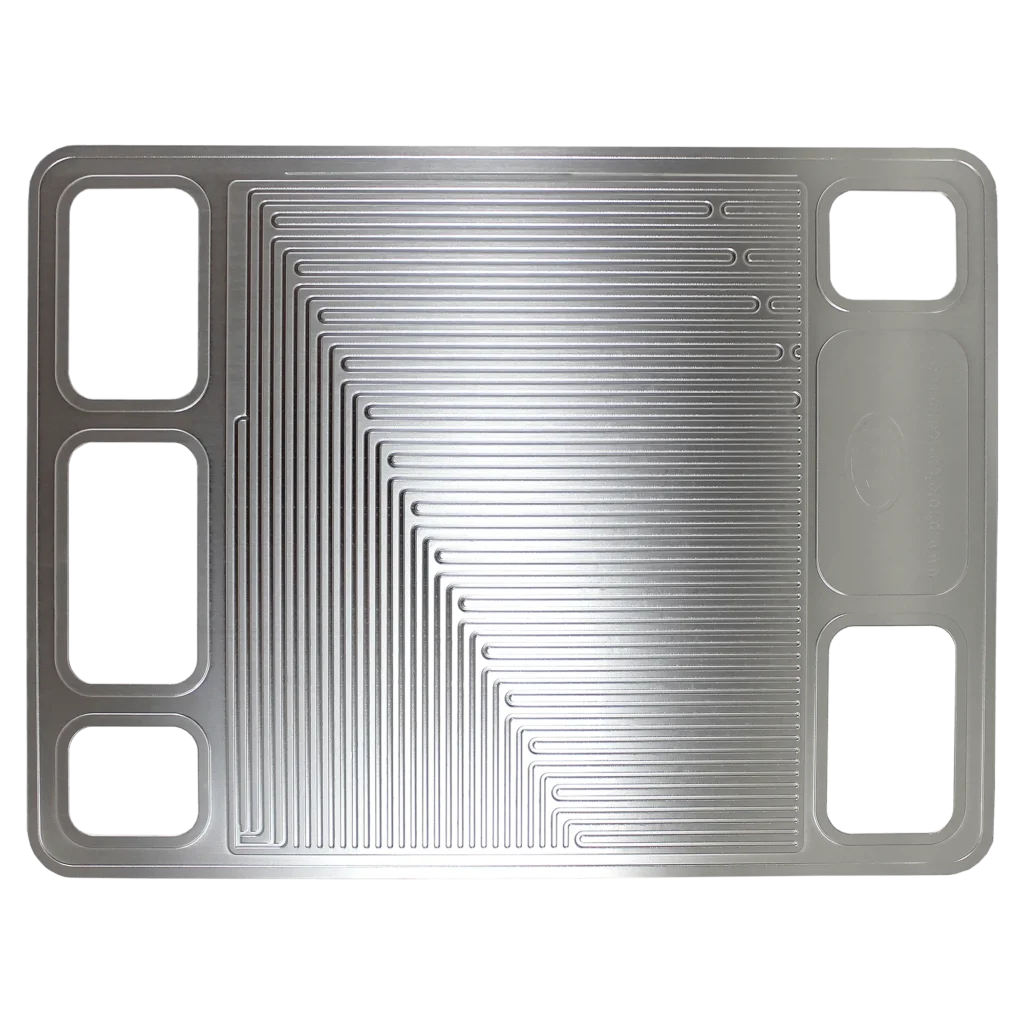

PEI is a leading producer of precision-etched plates for compact, high-performance heat exchangers used in advanced thermal systems. Our advanced photochemical etching process enables tight tolerances, complex geometries, and fast iteration without compromising material integrity.

The result is heat transfer plates that deliver reliable and efficient thermal performance across various applications, including medical, aerospace, electronics, and green energy.

Traditional stamped or machined plates can create burrs, deformation, or warping that undermine performance and reliability. Photochemical etching, on the other hand, delivers precise microchannel patterns that maximize heat transfer surface area, improve high heat transfer efficiency, and minimize pressure drop.

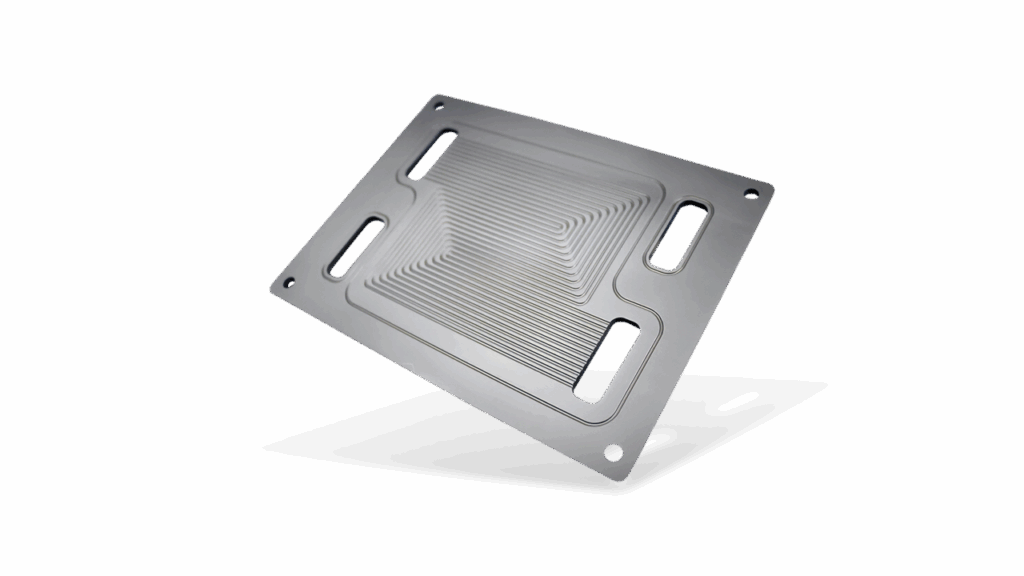

This burr-free process enables compact, lightweight thermal management solutions where efficient heat transfer is essential. Etched plates are ideal for a wide range of systems, including plate heat exchangers, tube heat exchangers, gasketed plate heat exchangers, welded plate heat exchangers, brazed plate heat exchangers, hybrid plate and frame designs, and even specialized pressure plates for demanding environments.

With etched channels, designers can control how hot fluid interacts across the heat transfer area, ensuring smooth flow paths, predictable heat transfer characteristics, and stable operation even under challenging temperature difference conditions.

PEI’s etched plates are engineered for mission-critical applications across industries where precision cooling and efficient thermal management make all the difference.

PEI’s photochemical etching process delivers unmatched precision and flexibility for heat exchanger plates. With the ability to produce complex designs in thin metals while eliminating burrs, stress, and distortion, our process ensures reliable and efficient thermal performance. From rapid prototypes to full-scale production, PEI provides a cost-effective path to innovation in compact thermal systems.

Essential for high-capacity, fast-charging batteries in EVs, supporting the shift toward sustainable transportation.

Key components in batteries used for storing energy from solar, wind, and other renewable sources.

Optimize battery performance in devices such as smartphones, laptops, and wearables.

Support long-lasting, reliable power in devices like pacemakers, hearing aids, and surgical tools.

Enable lightweight, high-capacity batteries for satellites, drones, and other advanced technologies.

Power autonomous systems, robotics, and other heavy-duty machinery requiring durable and efficient batteries.

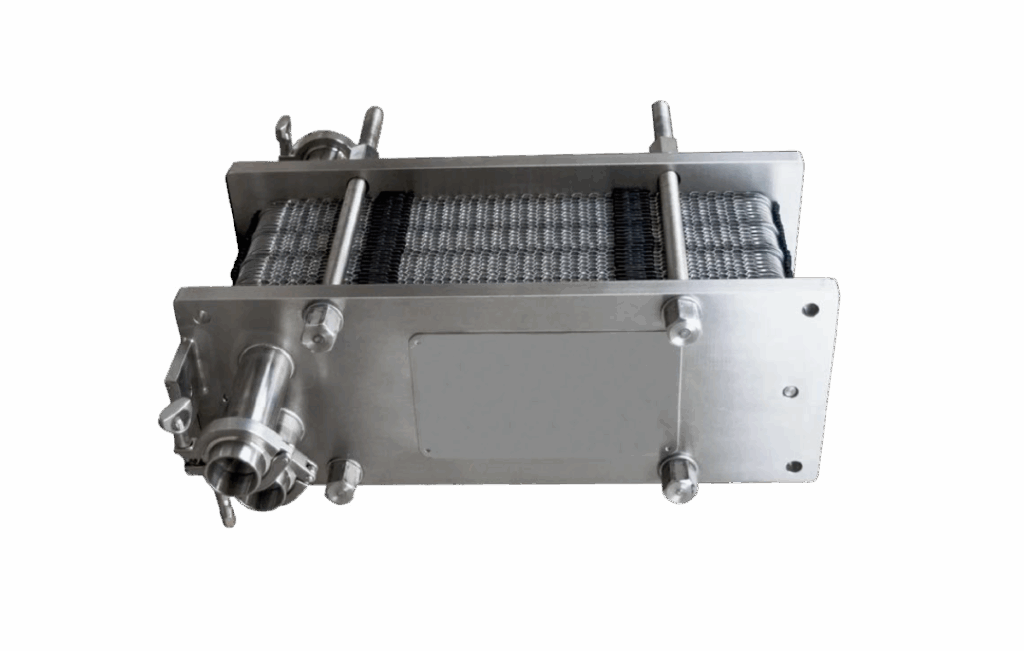

PEI sets the industry standard for plate and frame heat exchanger components, offering unmatched expertise in transferring heat through advanced plate design. With decades of experience in heat transfer systems, our ISO-certified U.S. facility delivers:

Whether your project demands compact heat transfer plates for hot fluid management or scalable solutions for large-volume plate heat exchangers, PEI is your partner in innovation.

Contact us Today to discuss your specific heat transfer area requirements or Request a Quote.