PEI’s custom EMI/RFI shielding solutions are precision-engineered to block interference, preserve signal strength, and protect sensitive electronics in critical applications.

An EMI/RFI shield is a thin, precisely engineered metal component that helps your electronic devices perform better, last longer, and stay safe from outside interference.

In simple terms, these shields act as a barrier against electromagnetic waves, blocking unwanted RF (radio frequency) signals and other sources of noise that can disrupt your device’s performance. By keeping external interference out (and preventing internal signals from leaking), EMI/RFI shielding ensures your electronics run smoothly, data transmissions stay accurate, and sensitive information remains protected.

Whether it’s a medical device, communication system, or aerospace instrument, effective RF shielding is critical to maintaining reliability and compliance in any high-performance electronic application.

EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) are disruptive electromagnetic fields that can compromise the performance and reliability of electronic components. These unwanted signals can cause data loss, distortion, and malfunction in electronic equipment, particularly in high-performance systems where precision is critical.

EMI/RFI shields are conductive barriers designed to block or redirect electromagnetic radiation, preserving signal integrity, protecting devices, and ensuring compliance with electromagnetic shielding standards. Whether used in aerospace navigation systems or medical imaging devices, effective shielding methods are essential for maintaining operational safety and regulatory compliance.

Maximizing shielding effectiveness requires the right combination of shielding materials, geometry, and grounding.

The best protection comes from:

PEI’s engineering team works closely with customers to evaluate each application, ensuring the electromagnetic shielding solution delivers maximum attenuation while maintaining mechanical integrity and serviceability.

PEI is a leading manufacturing partner of industry-leading companies serving the medical, defense, aerospace, and electronics sectors.

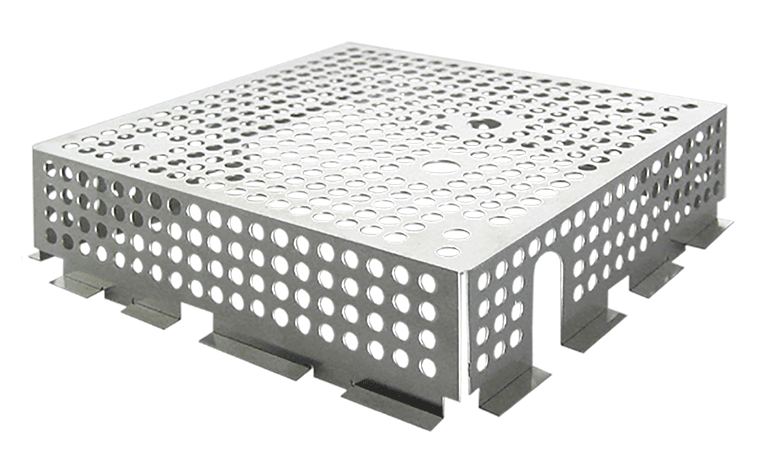

Our precision photochemical etching process eliminates the need for costly hard tooling, allowing for rapid design changes and producing complex geometries with burr-free edges – ideal for high-density electronic assemblies and delicate electronic components.

We offer a full range of custom shield types to suit virtually any electronic application. Our capabilities include one-piece and two-piece shield cans, as well as frames, removable covers, contact fingers, lids, and clips, each designed to meet your specific performance and packaging requirements.

We also bring deep material expertise to every project, working with a variety of EMI materials, including stainless steel, nickel silver, beryllium copper, brass, and custom alloys.

From rapid prototyping to high-volume production, PEI scales seamlessly with your project, delivering consistent quality, competitive pricing, and the flexibility to evolve your design as your needs change.

The PEI advantage includes:

PEI’s EMI/RFI shields ensure reliable operation of avionics, radar systems, UAVs, and satellite communications by maintaining clear signal transmission and protecting sensitive components from harsh electromagnetic conditions.

Our shielding solutions protect implantable and external medical devices from unwanted electromagnetic fields, ensuring accurate readings, stable operation, and patient safety in compliance with stringent medical standards.

From smartphones and IoT devices to consumer electronics and wearables, PEI’s custom shields help maintain signal clarity and device reliability in compact designs where space and performance matter most.

PEI’s shields provide robust protection for antennas, routers, and network hardware, reducing interference and maximizing system efficiency across complex wireless infrastructures.

PEI is ITAR-registered and ISO-certified, delivering consistent quality and traceability to meet the demands of regulated industries. As a trusted U.S. manufacturer, we provide secure supply chains and dependable service for mission-critical electronic components.

From design to delivery, PEI combines advanced shielding methods with precision manufacturing to protect devices across the most demanding applications.

Contact us for innovative and precise solutions.