April 10, 2024

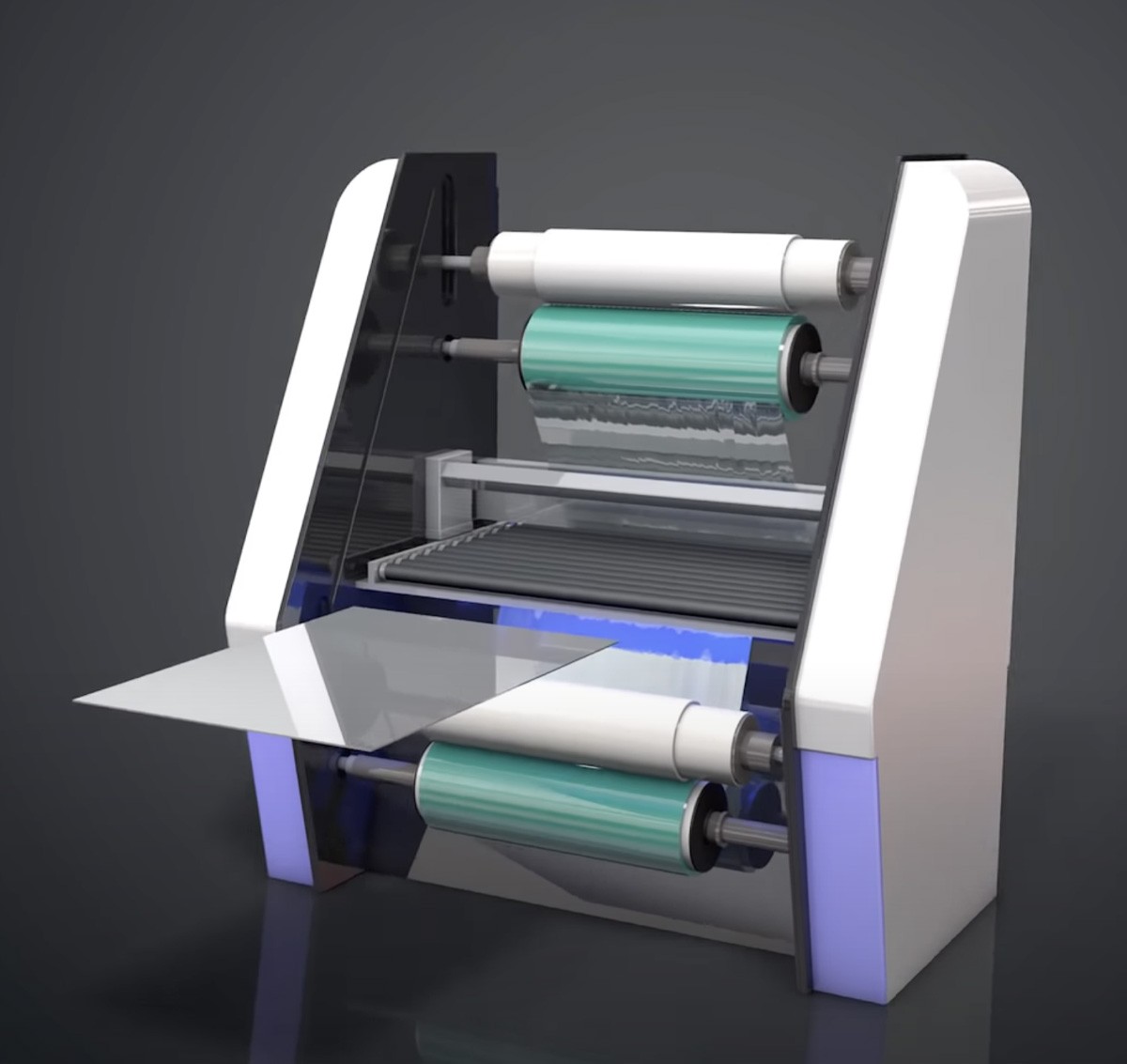

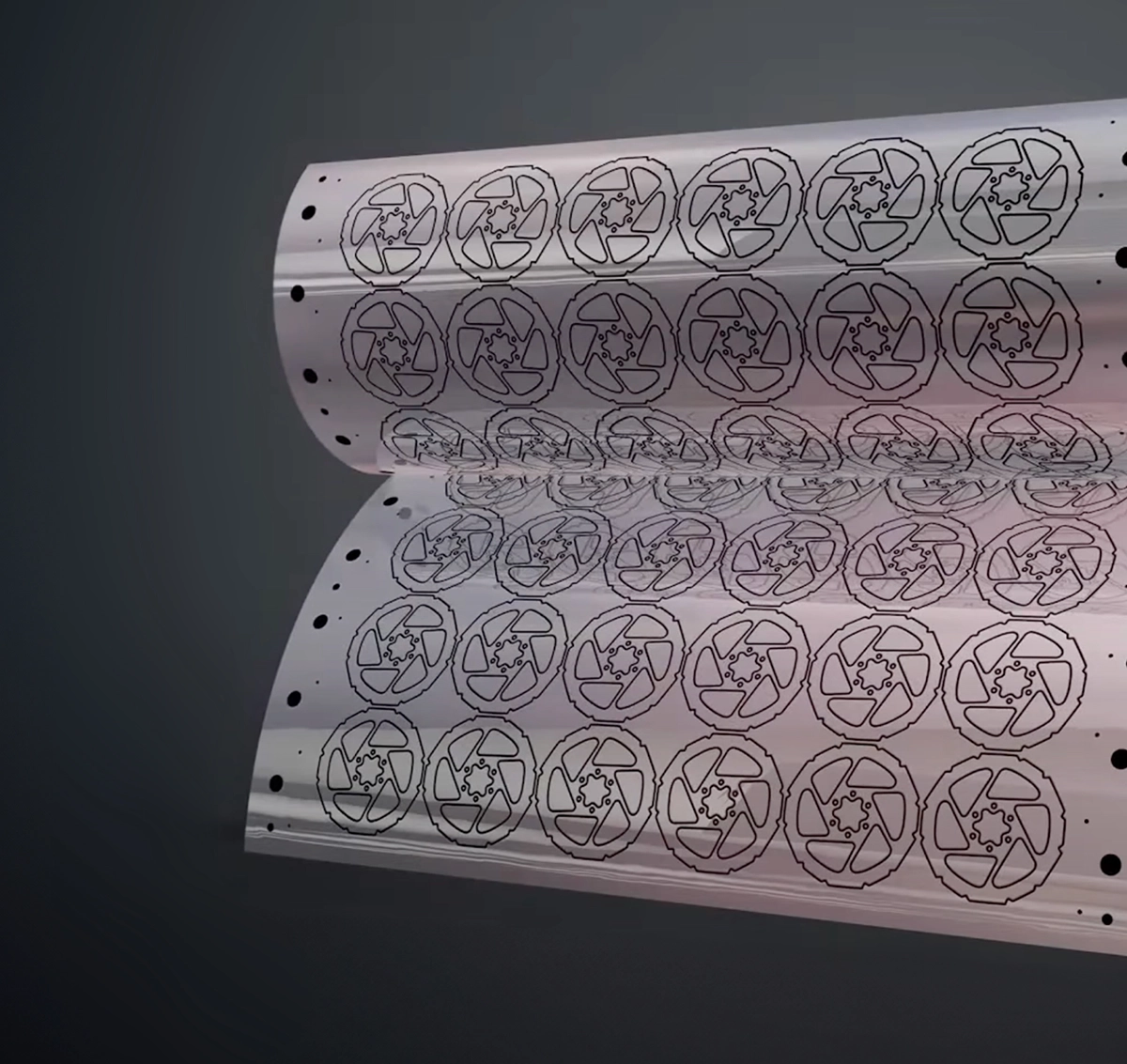

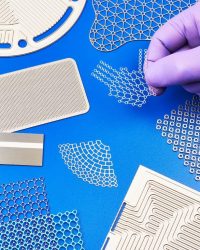

Explore the unique advantages photo etching delivers over traditional manufacturing processes and how this precision process is empowering designers and engineers to push the boundaries of creativity and innovation.

February 28, 2024

Discover why photo etching services offer unparalleled precision and consistency compared to traditional manufacturing techniques. Learn about the advantages, applications and why PEI is the trusted leader.

November 28, 2023

In this article, we dive into the transformative benefits of titanium etching and its applications that are vital across aerospace, medical, defense, and electronics.

October 25, 2023

Photochemical Etching (PCE) is transforming the renewable energy industry by providing unparalleled precision and environmental efficiency in the mass production of essential components like fuel cells, solar panels, and wind turbine parts.

September 14, 2023

In this article, we look at the tools, technology and processes required for precision and the crucial role precision metal parts play in reducing errors in precision mechanical assemblies.

August 8, 2023

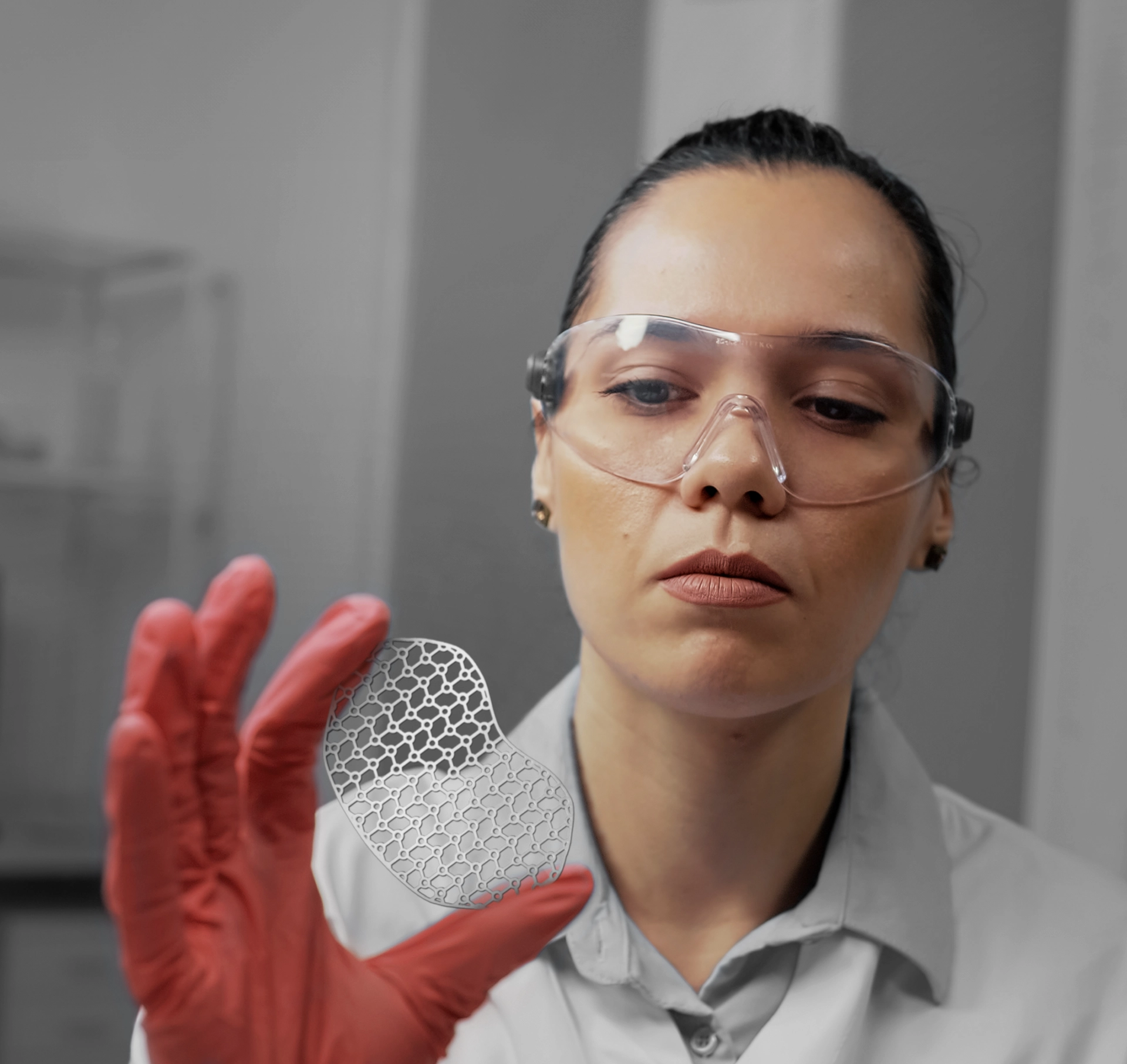

With no room for error, modern medical devices must be designed and manufactured using only the best quality materials and meet stringent safety standards. In […]

July 13, 2023

Discover how the photochemical etching of titanium is revolutionizing high-performance energy applications. Titanium’s exceptional properties, including corrosion resistance, lightweight nature, and strength, make it ideal for […]

June 19, 2023

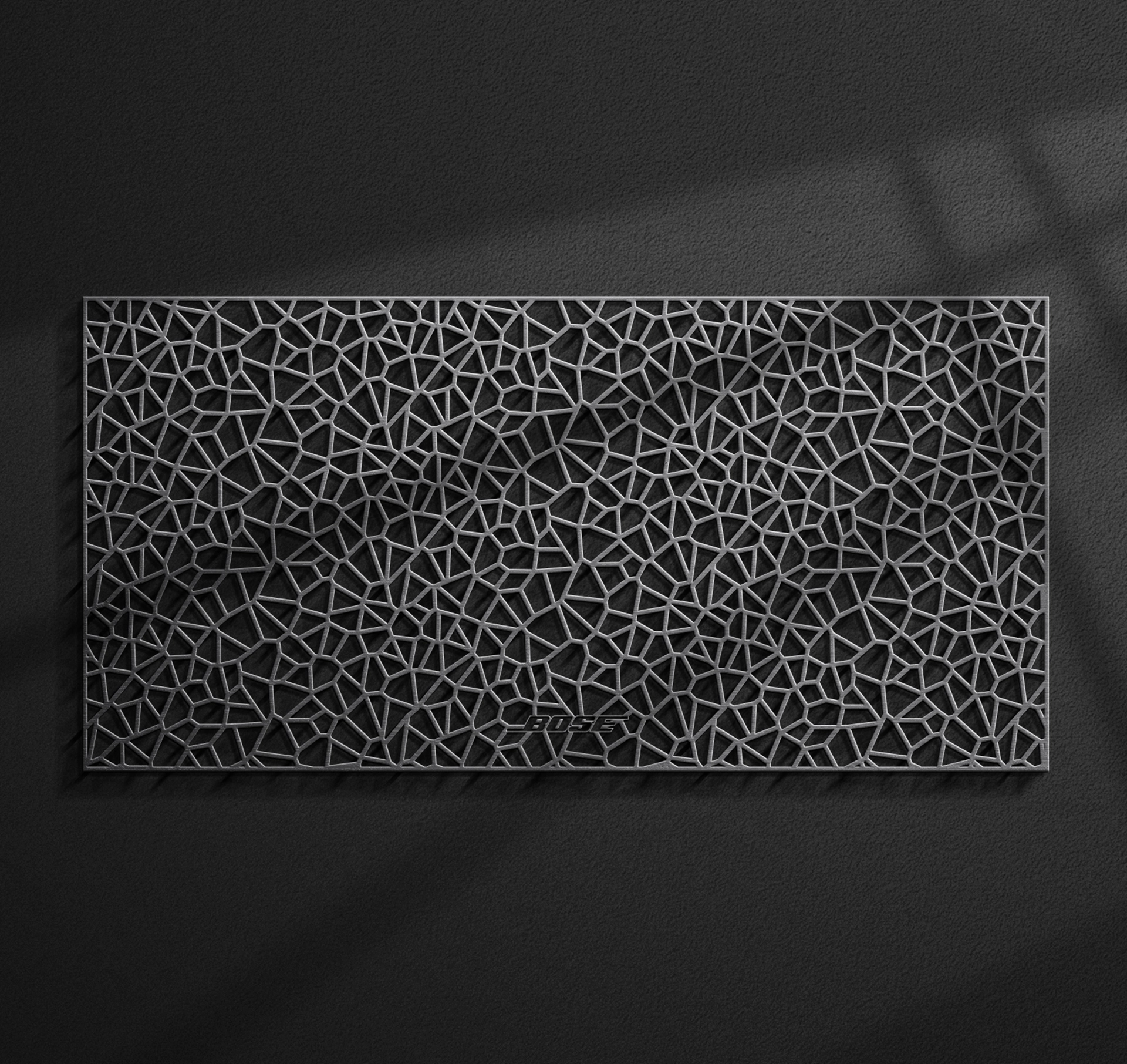

The PEI History of Innovation, Expertise, and Reliability Photofabrication Engineering, Inc. (better known as PEI) is a company that takes great care and pride in delivering […]

September 18, 2018

Photofabrication Engineering, Inc. (PEI) has introduced a wide range of standard and custom chemically machined, tight tolerance lids and covers designed for seam-weldable microelectronic. PEI Step […]

August 2, 2018

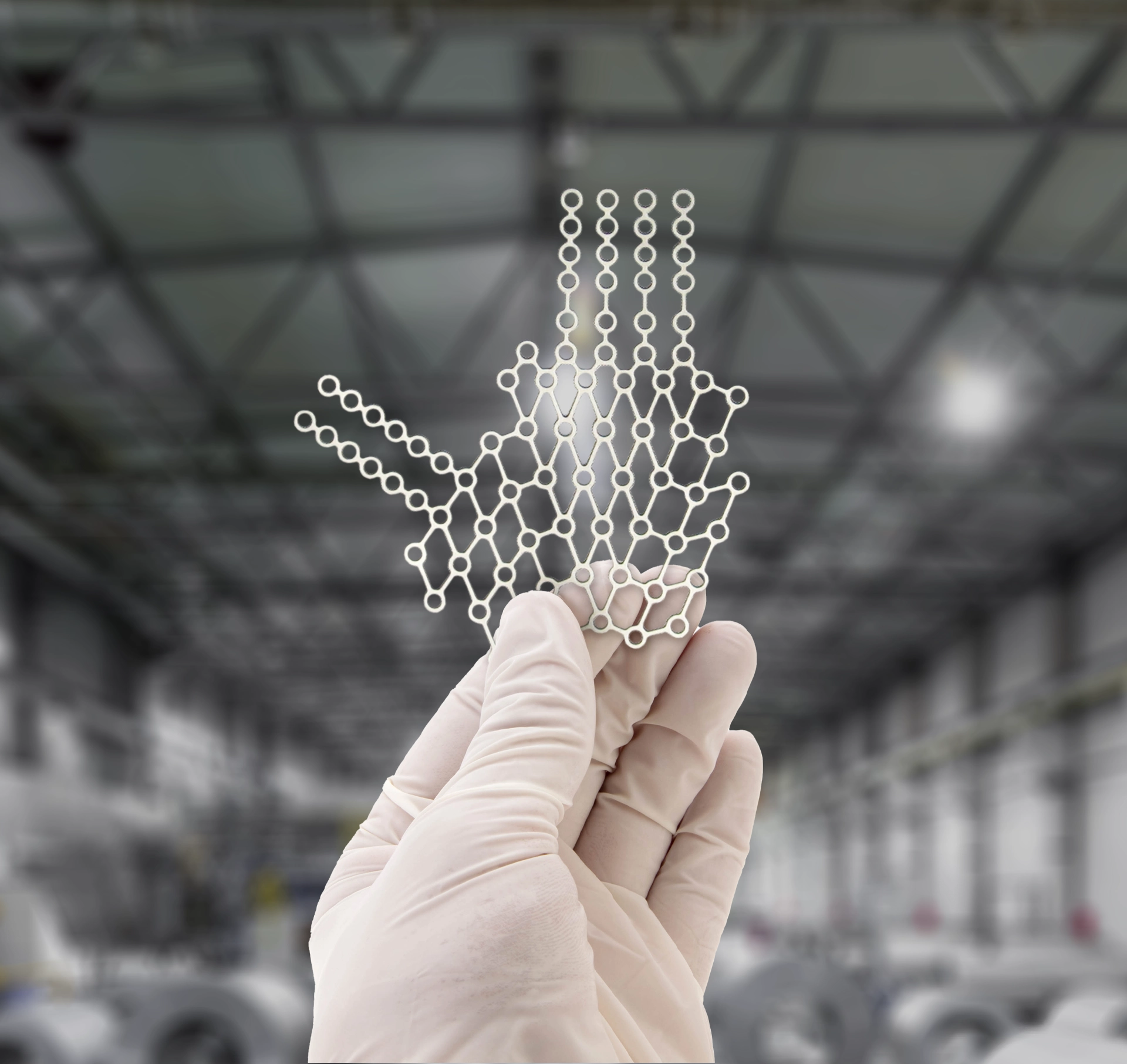

TITANIUM PARTS PRECISION CHEMICALLY MACHINED Custom chemically machined titanium parts for critical aerospace, battery, electronics, fuel cell, medical implantable, and related applications have been introduced by […]